I ordered a rebuilt alternator from a 1986 Toyota Corolla GTS. This unit is very small and is rated at 70A. It came with a complete test sheet with amps vs. rpm which prompted me to decide to use a larger diameter pulley to slow things down a bit for longevity.

I decided to reduce the alternator speed substantially from the stock Subaru setup which I calculated was turning over 15,000 rpm at redline. Since the aircraft engine spends most of its time above 4000, I changed the pulley ratio from 2.6 to 1.5. This still gives adequate ground charging at 1000 engine rpm and reduces vibrational stress and brush and bearing wear in flight.

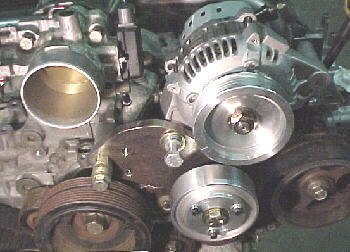

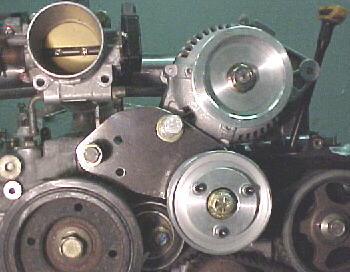

A new large diameter pulley was machined from 4 inch 6061 T6 billet. With no room for adjusting belt tension with alternator movement, I decided to build an idler pulley system. After trying various car dealers and finding their prices on idlers absolutely incredible, I bought a bearing for $7 good for 800 lbs. radial loading and 17,000 rpm. I then machined the parts you see here from my left over piece of T6. Both of these projects took a LONG time. They are very strong and look pretty as well. They will be hard anodized for wear resistance later.

The alternator mount was built from 1/2 inch mild steel plate, 3/16 X 1.25 angle steel and some T6 shafting. I wanted a very strong and rigid alternator attachment as I have seen too many things fall off other aircraft installations and racing cars. The alternator is quite critical on this installation and does you no good lying in the bottom of the cowling. Strength was more important than weight here but it still weighed less than the factory mount. The mount also encorporates threaded holes for the turbocharger truss located behind the harmonic balancer.

10/14/99 Alternator pulleys after hard anodizing and mounts after powder coating

09/09/03

It has been suggested in a "Contact" article that the Denso alternators suffer from excessive commutator shaft wear. In 25 years of working on Toyota engines equipped with various Denso alternators, I have never seen this condition, even in units with over 350,000 km on them. In fact, I have never seen any electrical failure on one of these except when the brushes actually wear down to nothing. This takes 1500 to 2000 hours in most cases. The type fitted to '85-'87 Corollas are the most reliable alternators that I have ever seen. Certainly more so than the Mitsubishi units recommended.