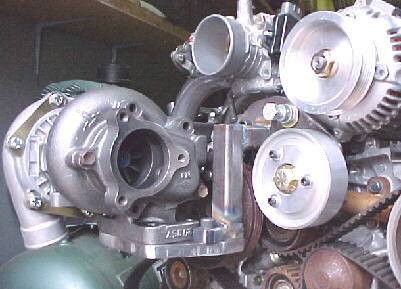

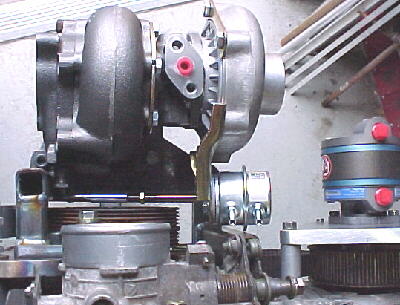

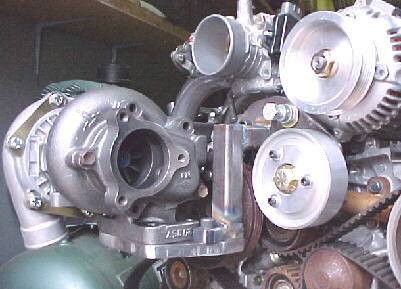

It was decided to rigidly mount the Garrett turbo to the engine and slip joint the 321 stainless pipes to allow for expansion. A turbine inlet flange was cut out of 1/2 inch mild steel. This flange incorporates threaded holes for the turbo mounts to attach to. The left mount was constructed from 1 inch, .125 wall square tubing and attaches to the block with two 8 X 1.25 bolts. The right mount was also made from the square tubing. It attached to the alternator mounting plate with two 3/8 NC Allen bolts.

The turbine inlet flange is centered laterally on the crankshaft centerline. Height of the turbo took into account oil drain height into the pan, intercooler plumbing clearance to the throttle body and exhaust and air filter plumbing clearance. Slight clearance was also provided from the harmonic balancer to allow for heat shielding material between it and the turbo. Again, strength, rigidity and ease of access were primary concerns on this structure. I plan to install the firewall recess plate offered by Van's for proper turbo to firewall clearance as it looks like the turbo would otherwise touch the flat firewall by about 3/4 inch.

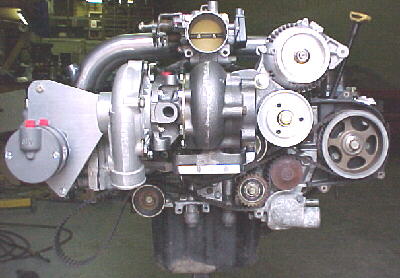

10/14/99 Turbine housing and wastegate swing valve housing after ceramic coating