Having completed the mounting and fabrication of most accessories on the engine, it was time to get into the engine. I was very impressed with the strength and rigidity of the EJ22 turbo engine. Unlike the EJ25, the EJ22 turbo has a closed deck block surface providing a much stiffer cylinder assembly and better head gasket sealing. Cast iron liners about .125 thick are cast right into the aluminum. This is an ideal setup. The block is a precision pressure die cast unit as opposed to most blocks which are sand cast. There are plenty of coolant passages in the head to block area and the wide bore spacing is good for turbocharging. The coolant flow path was well thought out with split passages in the block to force coolant from the lower block, through the head and back into the upper block. This uses natural convection to aid direction. Many other engines have a haphazard and unpredictable coolant flow design.

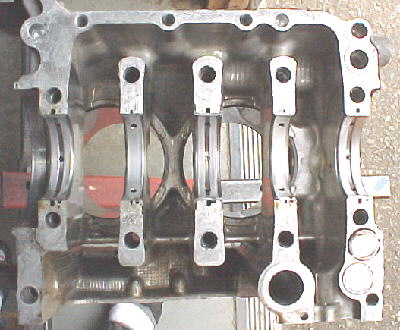

The turbo version also has piston oil jets to cool the piston domes under boost. Extensive ribbing in the casting on many of the water and oil passages help to dissipate heat from these areas. The block halves are attached with 10, 10mm bolts and 7, 8mm bolts, creating a very rigid design. The 3 center main caps which span the cylinder bores are 2 inches thick and carefully radiused to preclude any chance of cracking. With 26,000 miles on this engine, it exhibited no detectable wear on the bearings, rings, bores or crankshaft.

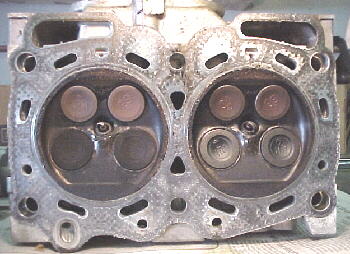

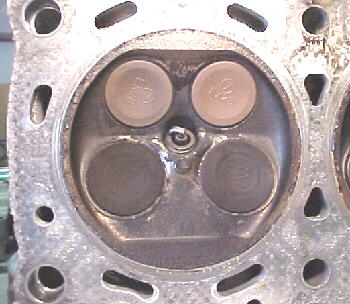

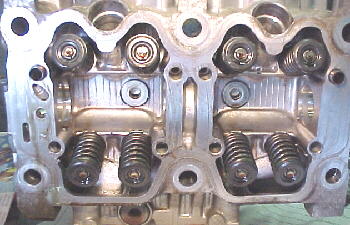

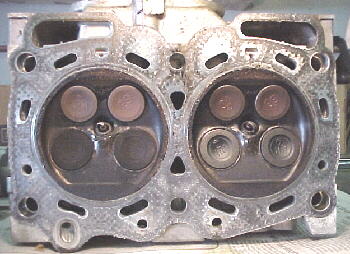

The heads are compact, easy to work on and well provided with cooling passages. 6, 11mm bolts hold the heads to the block. These are very long and go right into the base of the block so that there are less localized stresses present in the block deck. A really good idea. The intake valves measure 31mm and the exhausts are 28mm. Not overly large, but adequate for the intended 4000 to 5000 rpm operating range. Exhausts are all stainless and had no wear at all on the stems. In fact, all the factory Parkerising was intact.

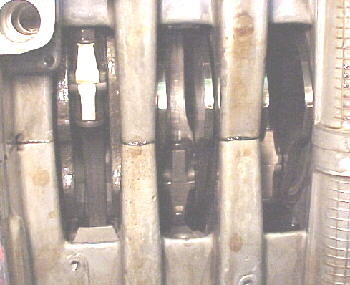

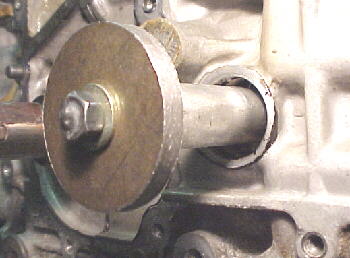

The piston pins are removed through plugs in the block with the pistons at BDC. This is somewhat unusual, time consuming, awkward and annoying however, it does allow for a more rigid block assembly than an open block design would permit. I machined an expanding arbor tool to extract the pins through these holes.

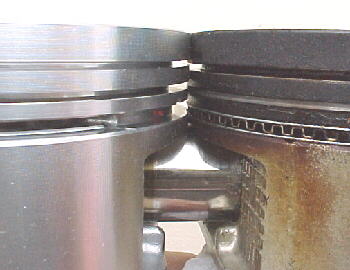

The turbo pistons are typical cast types with a 8 to 1 CR. The pin is 23mm in diameter and has a massive .190 wall for rigidity. The turbo pin is somewhat longer than the naturally aspirated pin as shown below. The turbo piston has the upper ring grooves moved down slightly for less heat exposure but the ring lands are relatively thin and this is where cast turbo pistons generally fail. Surprisingly, the piston dome on the turbo piston is thinner than the naturally aspirated piston at .145 inch vs. about .210. The pistons will be replaced with forged 2618 alloy pistons having a 9.6 to 1 CR. Naturally aspirated piston left, turbo right.

The connecting rods are well designed forged alloy steel. They are short and stiff, measuring only 5.25 inches center to center. They are fitted with high quality 9mm ultra fine thread bolts. Bronze pin bushings are pressed into the thick walled eyes.

The crankshaft is a beautiful piece. It is forged and heat treated steel and weighs only 20 lbs. Total length is only 13.5 inches. The short stroke design gives about .750 inch of crank pin vs. main journal overlap, making it very stiff. Oiling is reasonably well thought out. The crank fillets are rolled for low stress and fatigue resistance. Journal diameters are 2.36 mains and 2.05 on the rods, about average for a 2.2 liter engine. The crank is fully counterweighted, which shows that Subaru valued smoothness.

My overall opinion of the EJ22 for aircraft use is that it is very well designed, extremely stiff and strong, uses good metallurgy and should make a fine aircraft engine with minimal changes. The design is several generations ahead of standard air cooled aircraft engines. The liquid cooling, overhead cam, 4 valves per cylinder, 5 main bearing design with high compression ratios is how things should be done, approaching the next century. This engine is composed of many more parts than a conventional inline 4 cylinder automotive engine and certain unique procedures and tools must be employed to service and overhaul it. Being a relatively complex split case, aluminum design, it demands more care and patience than most auto engines do. I would not recommend that inexperienced people start ripping into one of these. If you don't know much about engines, stick with a low mileage, naturally aspirated EJ25. Just leave it together and fly it.