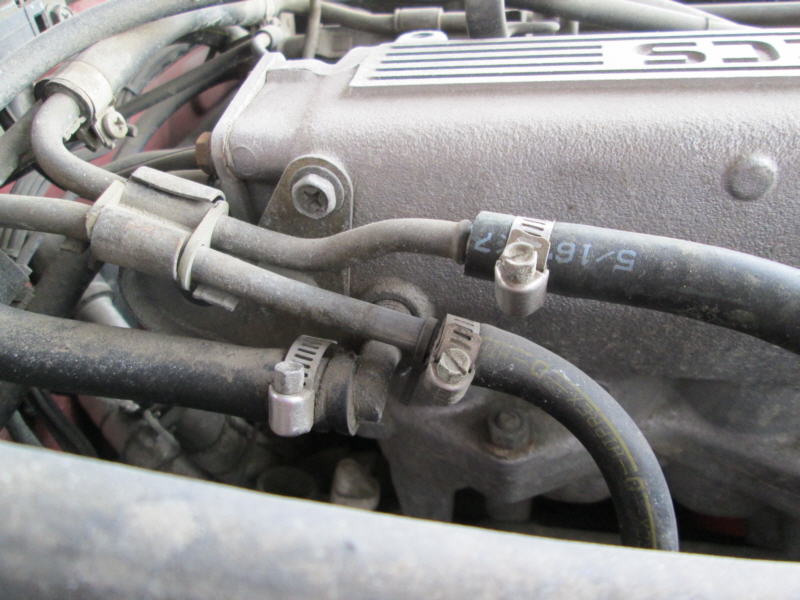

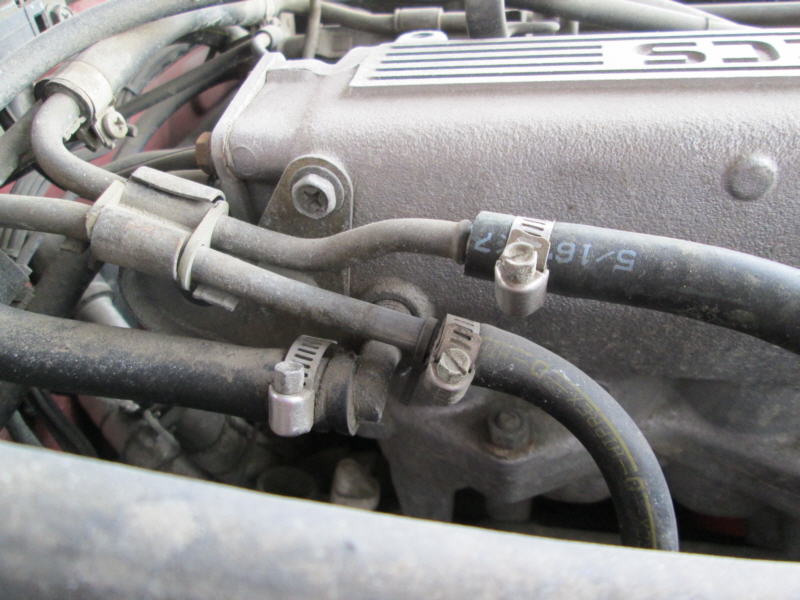

Shop 240SX turbo owned for 19 years with OEM barb fuel connections. Over 5000 hours, no leaks. Fuel pressure under boost up to 53 psi.

Let me start off by saying that the choice of EFI or carb in experimental aviation is primarily based on preference and possibly cost on some lower hp engines. If you like a carb and it works for you, that's great, you'll probably stick with it. This article is primarily in rebuttal to the misinformation presented on the FlyCorvair site: FlyCorvair

The author has limited experience with EFI in aircraft and automotive worlds and therefore makes many erroneous statements about it. Most of his arguments have no basis in fact or logic and fly in the face of modern developments in both the auto and light aero engine industry today. Perhaps the author is smarter than the engineers who work for these engine companies? I have 35 years in the automotive repair/racing segments and aviation fields and have been working with EFI since 1984, manufacturing and marketing programmable EFI systems for auto and aviation since 1994 with over 9,000 units sold all over the world.

I'll address each point as it appears in the article:

1. Power. EFI will often produce slightly more power than a carb. This is because cylinder to cylinder mixture distribution is better than most carbs can offer and secondly, no restrictive venturi is required with EFI. More mass flow through the engine due to less restriction = more power.

2. Fuel Consumption. Again, due to superior mixture distribution and the precision in which fuel can be metered under all conditions, fuel injection has been shown to reduce fuel consumption markedly. On some Continental O-200 engines, which have very poor induction setups, customers have reported fuel flows were reduced up to 20% over the carb setup for the same TAS.

3. Carb Heat. Obviously with fuel being injected into the hot port at the back of the valve and without fuel being vaporized in the venturi like in a carb setup, there is no possibility of carb ice and no need for carb heat. Carb heat reduces mass flow and thus power when used as well.

4. Reliability. The reliability of EFI is well proven in the automotive world (trillions of hours since 1967) and we use the same OE fuel hardware in most cases. It's the single most important technology introduced in that industry which drastically reduced maintenance and improved reliability. I used to fix and adjust carbs for a living long ago and that work pretty much went away entirely when EFI use became widespread. Most EFI cars require no maintenance with the fuel system for the entire life of the vehicle. No production cars have had carbs for over 20 years. EFI is also proven in aircraft. Our systems alone have accumulated over 450,000 flight hours to date.

Regarding the EFI V8 Lancair, the author states they had the "best system and best people" working on the project. How could they be the "best" if it was their first EFI installation and why did it take a lot of hard work to get it functioning properly if they were so talented?

The author is "certain" somehow that there are only about 300 EFI aircraft flying in the US. Hmmm we've sold over 1000 systems in the US alone for aircraft and there are hundreds more flying with OEM EFI on them. Rotax, D Motor, UL Power and several VW based engines also come from the factory now with EFI. No modern aero engine would have carbs on it today just as no car would.

The author also does not know of any aviation records being held by low powered EFI aircraft. I guess he doesn't know Klaus Savier from Lightspeed who holds many speed/ distance records with his EFI O-200 powered Eze. Maybe he doesn't follow SARL racing either where Russell Sherwood won his class with an EFI Subaru/ Glasair. We've had dozens of customers flying EFI on VWs and small Continental engines for many years. Reliability according to the users, has been superior to their old carb setups and none of them would retun to carbs. Fundamentally, there is very little difference between EFI hardware for automotive and experimental aviation. We take the reliable and well proven OEM parts from the auto industry and get the same results in aviation. We've been doing it for over 20 years with installations on 20 different brands of engines fitted to aircraft. The author goes on to claim that barb fitings are not safe on fuel systems at 35 psi. Hmmm, I wonder why auto OEMs for 20 years used them on EFI fuel systems, including the high pressure end. Tens of millions of these have tens of BILLIONS of hours of safe operation on them.

Shop 240SX turbo owned for 19 years with OEM barb fuel connections. Over 5000 hours, no leaks. Fuel pressure under boost up to 53 psi.

Shop RV6A flown for 14 years with barb fuel connections on fuel pumps. Over 400 hours to date. No leaks.

1. Fuel injection usually makes more power than a carb setup. I've put injection on dozens of carbed engines and dynoed them before and after. I've never seen a case where the EFI lost power and seen some significant gains at lower rpms due to superior atomization and equal distribution between cylinders. Cooling from fuel vaporization in a carb manifold is better than EFI? Nonsense. The same mass of fuel is being vaporized so charge cooling is identical, just occurs at different places in the engine- port, in the case of MPFI.

2. Despite the author's contention, we've proven many times that EFI can significantly reduce fuel flows at the same TAS, especially when combined with ECU controlled ignition. The author claims that some EFI systems (referring to SDS I would assume) have crude fuel metering because programming steps in the rpm ranges are 250 rpm (now 100 rpm) apart. This shows he has no fundamental understanding of how SDS works. It's natural to fear and bad mouth what you don't understand or any have experience with. RPM Fuel Values only compensate for volumetric efficiency changes and this changes only fractionally over that small rpm range. The ECU multiplies MAP by the rpm fuel value then adds corrections for IAT. As such, there are approximately 200,000 possible points in the map. Some systems can target any desired AFR through wideband feedback control at multiple load points. EFI also allows you to run LOP if desired. A carb cannot. This can save over 20% in fuel flows.

3. Without a carb, you can't have carb ice. Since only air flows by the throttle body and there is no venturi, there is no local cooling to condense water vapor to form induction ice with EFI. Impact and airframe icing is possible on any aircraft flown in IFR conditions, obviously you'd want a second induction air source in any aircraft, carb or EFI if you operate there. I've got over 25,000+ hours in EFI cars and aircraft, never had induction icing yet, even with cold air snorkels, in driving rain, snow and temps down to -38C.

4. We run filters on pumps just like with carbs. All injectors also have screens internally. EFI components are no more likely to get plugged up with debris than a carb and we don't have to worry about floats and needles sinking and leaking either. See multiple ADs with regards to carb and float problems. SAIB. Of course EFI, like any other part in an airplane requires care and skill to install. If you can't crimp or connect wires properly, you should not do the installation just like if you can't tighten bolts and fuel or brake lines properly you shouldn't be doing it. EFI operates at pressures lower than the oil pressure of most engines and a lot lower than brake line pressures. Do we worry about leaks on those systems in aircraft? We've proven that our EFI systems can take the pounding of the Baja 500/1000 races which are far more punishing in terms of impact, G loading, temperature, moisture and vibration than anything in the aircraft world. We've proven you don't need billions of dollars to make EFI reliable nor do small companies like UL power or D motor.

5. We've had hundreds of people worldwide with normal mechanical skills successfully install and fly our EFI systems in aircraft, our first customer back in 1994 flew his Suzuki powered aircraft for 18 years and over 600 hours- no problems. We have several individual customers with over 1500 flight hours each on our EFI. We've had people install our systems successfully operating out of a small home type shop with a just a drill press and simple hand tools. You don't need to be a Guru to do it. Just follow our well proven recipe.

"Those that say it can't be done, should get out of the the way of those doing it"- Chinese Proverb

Ross Farnham