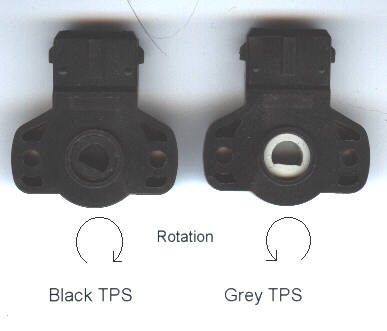

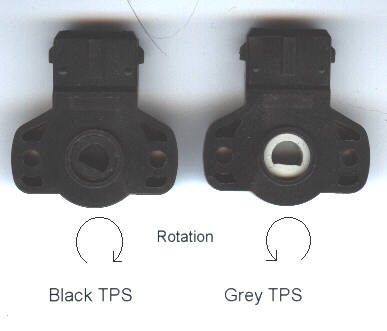

One of these two TPS sensors can be supplied with EM-4 systems. The arrow indicates direction of rotation. The photo shows which way the drive tang rotates. Be sure to select the proper sensor so that your throttle shaft will turn the tang the proper direction when installed. This can be confusing, so THINK about it. In the price list, the direction of rotation describes which way the THROTTLE SHAFT rotates as opened with the TPS DRIVE END of the SHAFT FACING YOU. It is important that you do it this way only as about 50% of people ordering TPSs are looking at it the wrong way and get the wrong one. We want to know which way the TPS END of the THROTTLE SHAFT rotates as it is facing you, as it is opened. Then we can send you the correct one.

The sensors have their own return spring inside. They fit a 5/16 inch or 8mm "D" shaft as found on many Japanese and European cars. Mounting hole spacing is 32mm or 1.25 inches, different from most throttle bodies. An adaptor will most likely need to be machined. Mounting hole diameter is .165 inch or 4 mm. Maximum shaft depth into sensor is .500 inch or 13 mm.

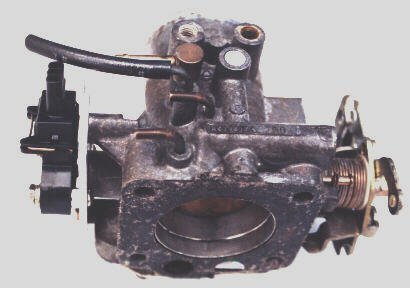

Photos below show the TPS sensor mounted to a throttle body using a small piece of 1/8" thick aluminum. The only tools required to make this are dial calipers, drill, center punch, and possibly a countersink. In this case one of the screws mounting the plate to the throttle body had to be a flathead screw and therefore required a countersink of that hole. This adapter plate has to be user fabricated as it is not supplied with the S.D.S. systems.