Last Update: April 29/19

Air Temp Sensor Connector Assembly

The GM air temp sensor (and coolant temp sensor if used) connectors are different from most of the other SDS connectors in that the wires are pulled through the connector PRIOR to crimping the pins on.

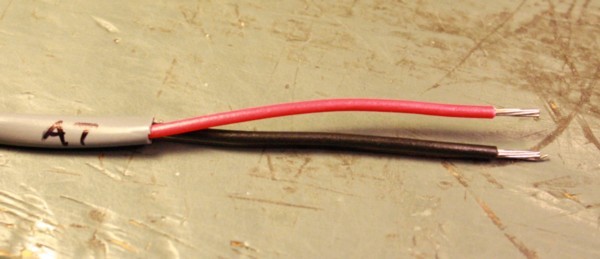

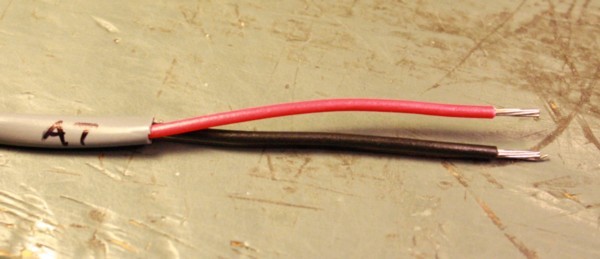

Step 1: Strip the outer sheath back about 1.75 inches and strip off the wire insulation for about .2-.25 inches as below

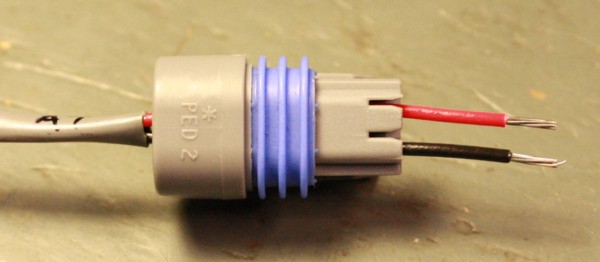

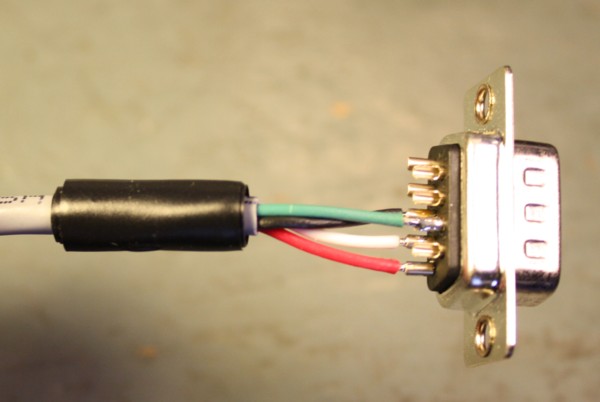

Step 2: Insert the wires through the connector with the locking tab facing down as below

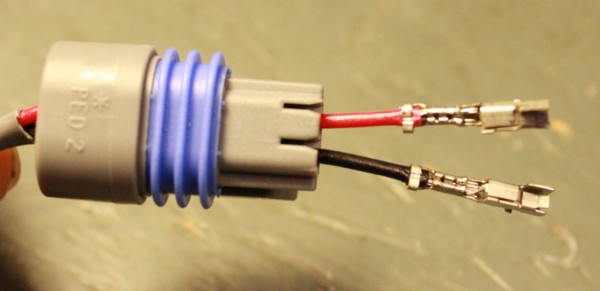

Step 3: Crimp the pins onto the wires as shown below

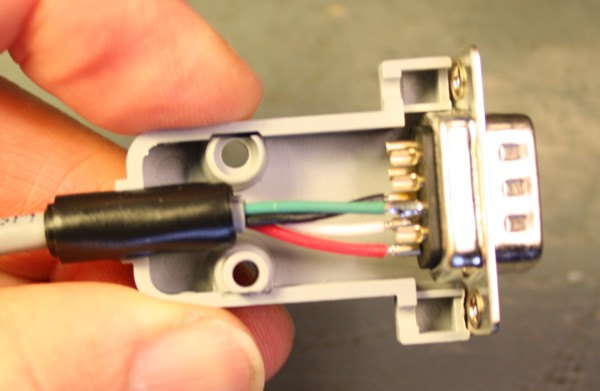

Step 4: Pull the wires and pins backwards into the connector while aligning the top blades with the slots until the pins click into the connector as below

Stripping Tefzel Multi-Conductor Cable

Here's a step by step guide to preparing the engine side ends of your harness

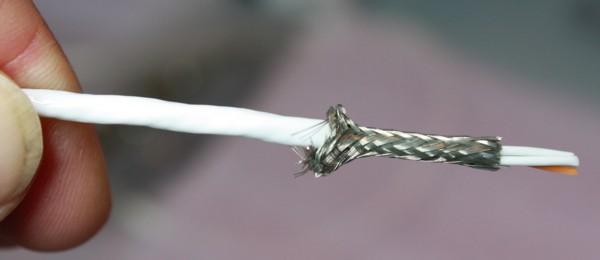

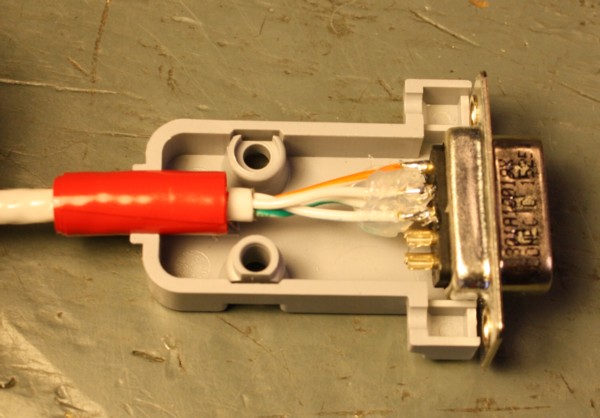

Score the outer insulation down to the braid without cutting through the braid

Pull insulation forward

Compress braid downwards so it bunches up

Using sharp cutters, cut the braid all around the cable

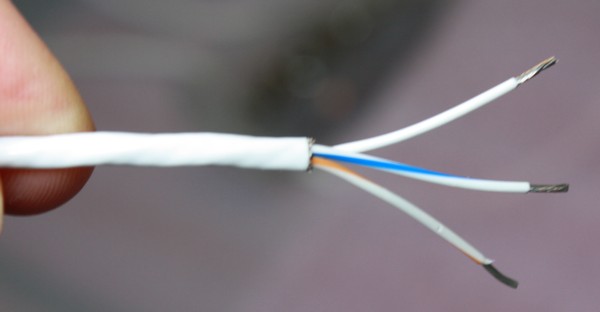

Remove braid and strip conductor insulation

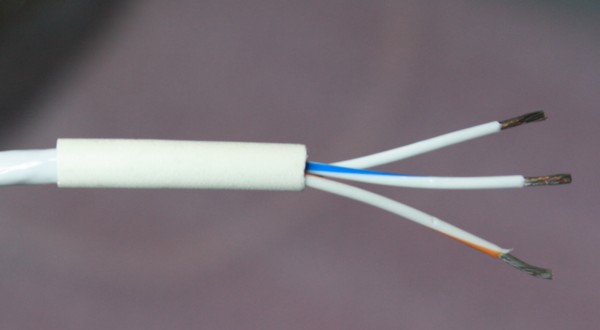

Apply heat shrink tubing so it extends over braid junction by about 3/16 inch

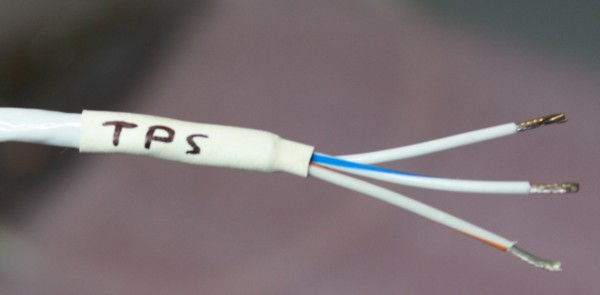

Shrink the tubing with a heat gun and label each cable

Hall Sensor Strain Relief

You must support the cable in the DB9 shell as shown below. We wrap electrical tape around the cable until it fits tight inside the shell exit.

We also put a dab of silicone on the wires where they are soldered into the back of the DB9 connector for extra vibration resistance as shown below.

Tip on Assembling MSD Spark Plug Wires

In order to get the boots to slide over the terminals and wires, lubricate the wire/ terminal OD and boot ID with alcohol based hand sanitizer. This will help things slide together much easier and will evaporate within a few minutes.

YouTube video here: Building MSD plug wires

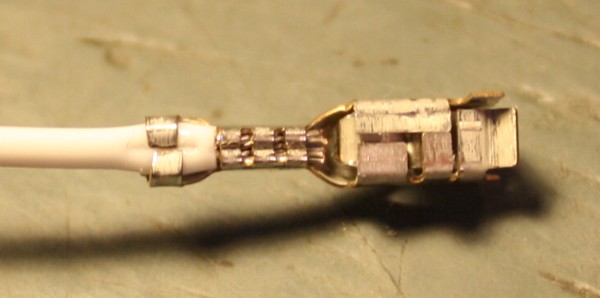

Proper injector pin crimp

For crimping most of the Weatherpack pins supplied with your system, you can order https://www.amazon.com/gp/product/B002CCAEJ6/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1.