Phone 403-671-4015

E-mail:racetech1@telus.net

Last update Jan. 21/26

Please note: As of Sept. 17/25, direct mail shipments under $800 to the USA are subject to 35% tariffs. We are presently working with a broker in Montana to facilitate tariff free clearance under USMCA agreements. Most shipments will go via USPS and they charge 2% of invoice value to clear and process shipments. We are not able to ship by Fedex any more. Some non USMCA kit components will be deleted from kits to avoid high tariffs and we'll provide part numbers and sources for you to order these parts from the US. The tariffs have created big delays in getting kits done and shipped due to the massive amount of paperwork required now. Lower value shipments will be sent directly by mail and we have to charge the 35% tariff up front. Sorry, we cannot expend the time to file the USMCA paperwork on these items.

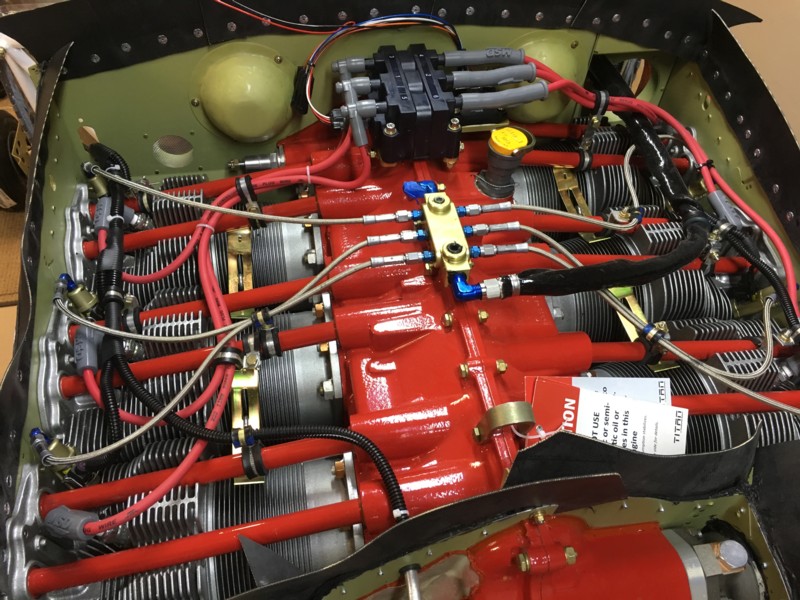

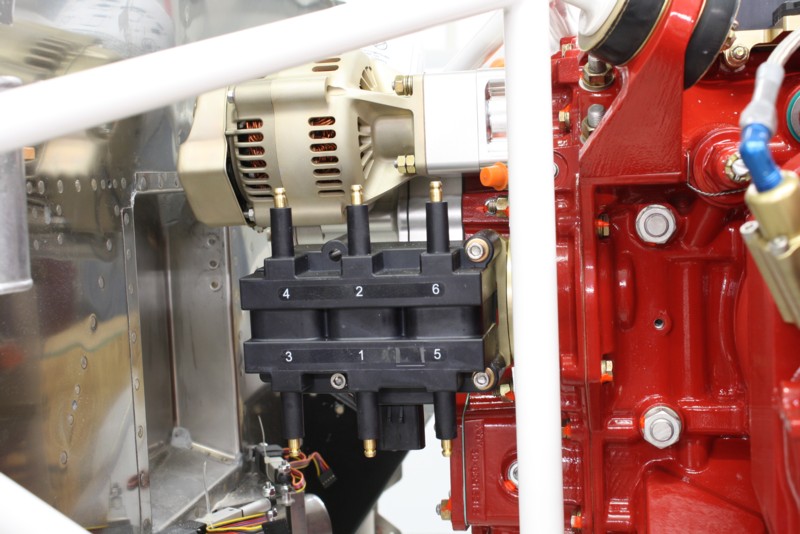

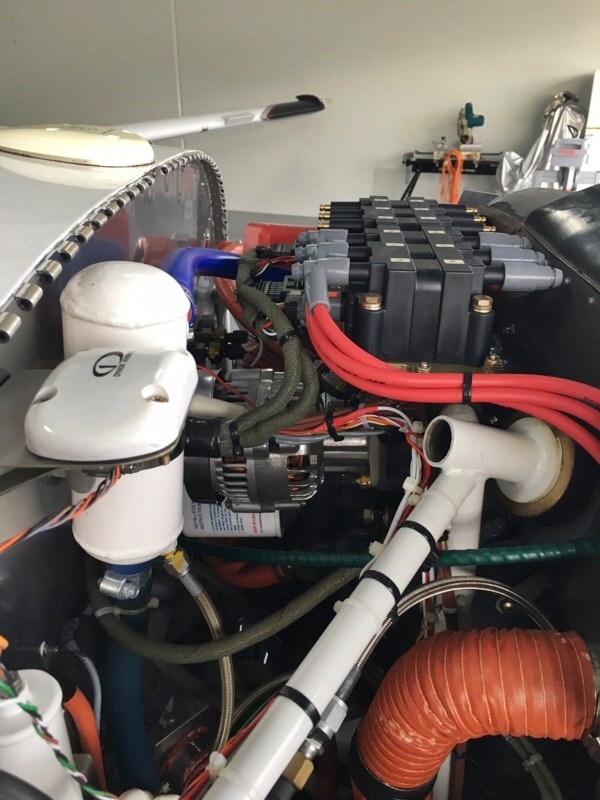

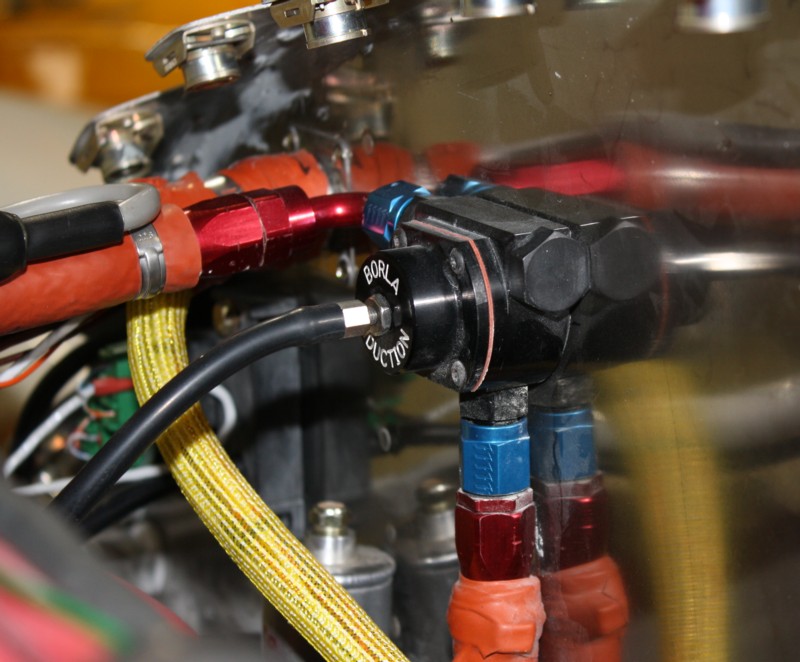

Basic components of EM-6 6F aircraft EFI system for Parallel valve Lycoming 540 with horizontal induction. No wiring shown here.

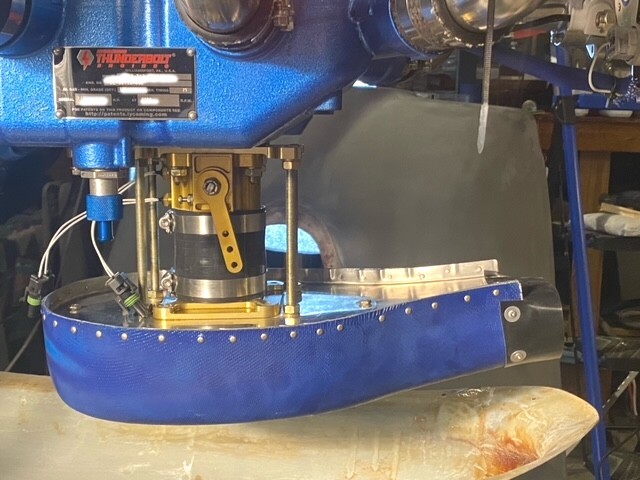

Ron Gawer's SDS equipped 540 on the dyno at Ly-Con. Sports SDS Aero billet flywheel and billet valve covers.

IO-540 on test stand at Aero Sport Power

Please be aware that there are numerous variations among Lycoming engines themselves and clones versions as well. Some parts may not fit or may have to be modified in certain cases.

To place your order, it's best to email or phone us to discuss your project as each system is custom made and tailored for each client. We'll get a list of all your details, discuss wiring lengths, colors, options etc. and then quote you. You then pay by Visa or Mastercard, wire transfer or E-transfer for Canadian customers.

Phone 403-671-4015

E-mail: racetech7@proton.me

Please email us for an exact quote- E-mail: racetech7@proton.me

Optional items:

Individual cylinder fuel trim $300

Card data logging $240

Digital fuel flow output to engine monitor $100 (eliminates Red Cube mechanical flow transducers)

To place your order, it's best to email or phone us to discuss your project as each system is custom made and tailored for each client. We'll get a list of all your details, discuss wiring lengths etc. and then quote you. You then pay by Visa or Mastercard, wire transfer, E-transfer for Canadian customers.

Phone 403-671-4015

E-mail: racetech7@proton.me

When replacing legacy mechanical injection, carbs or mags with EFI/EI, you may want to delete items no longer required. Thunderbolt and certain engine builders will delete these items and take them off the price of a new build. Below is a list of parts not required when fitting SDS EFI:

1. Mags, ignition harness, spark plugs

2. Servo, flow divider, lines, injectors

3. Carb

4. Fuel pump and pushrod

5. Flywheel. (Note that new Lycoming flywheels may lack the 12 tooling holes which we use to mount the magnet drilling block to).

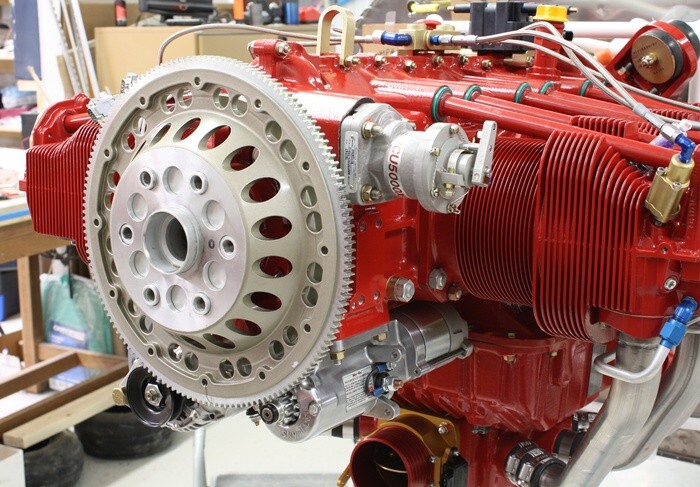

Your factory Lycoming flywheel must measure 9.75" OD where the belt groove is. Smaller flywheels measuring around 8.5 inches OD are not compatible. It must also have the 12 tooling holes just inside the ring gear area to be able to be drilled for our magnets. If it doesn't have these holes, you'll need to get one that does or buy our billet flywheel.

Please note: our magnet mounting system for Lycoming engines is not compatible with the Sky Dynamics lightweight flywheels, new Lycoming flywheels lacking the 12 tooling holes around the periphery or factory dual pulley groove flywheels. We do have a solution for Airflow Systems aftermarket flywheels for driving a/c compressors and a special drilling jig for these.

Magnets installed in AFS flywheel for use with their air conditioning system on RV-10s.

Krea Ellis' super clean 540/ RV-10 installation

Hall sensor cable protection detail

Mike Robinson's 540 Rocket

https://www.youtube.com/watch?v=Je0-Apg5JdM

Hot start video on Mike's Rocket

Steve Murray's very clean IO-540 installation

Les Kearney's RV-10

Video flying SDS EFI in Les Kearney's RV-10

Les Kearney's Aero Sport IO-540 with dual SDS EFI EM-5 and SDS Aero billet valve covers

SDS 80mm throttle body on Barrett cold air intake

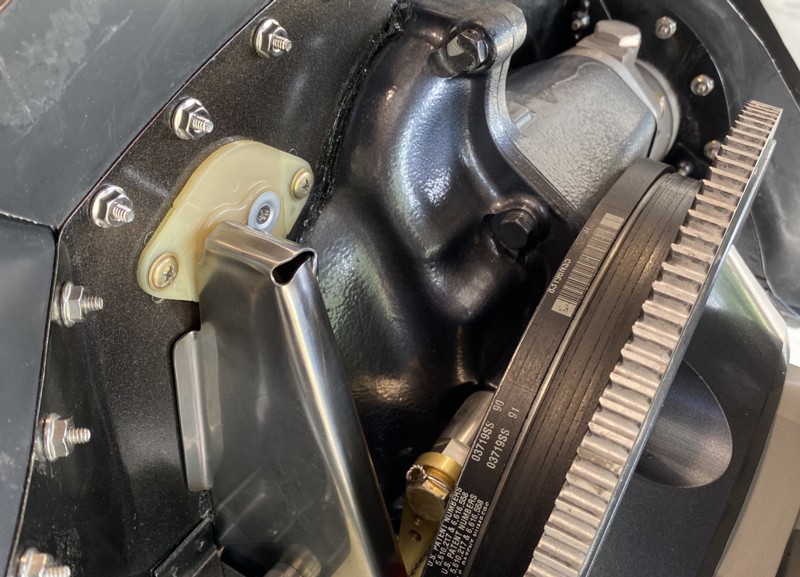

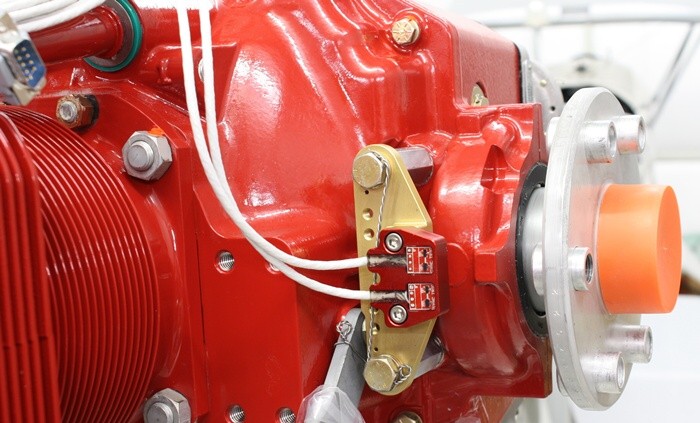

Crank sensor mount detail

SDS lightweight billet flywheel

Rear coil mount and backup alternator detail

https://rv10.ca/ Resource for RV-10 specific information- building, SDS EFI.

Ashley Miller was kind enough to bring the following to our attention; It seems new Lycoming Thunderbolt engines may come with flywheels which lack the tooling holes to locate our magnet drilling jig. In these cases, you'd have to obtain an older flywheel or get one of our SDS billet ones.

Gaylon Koenning's beautiful RV10 is flying with the dual SDS EFI system in Texas. 550 flight hours to date.

New boss/ injector combo for Reno 2019. 1/4NPT boss fits AV engines. Supports 660hp on 360/390 engines and 1000hp on 540/580 engines.

Standard boss for parallel valve Lycoming engines mounts EFI injector in original injector hole. Uses an injector with a stainless steel body for low heat transfer, proprietary high strength- low heat transfer, alloy steel, lower spigot, 7075-T6 retainer ring, stainless cap screws. Threaded adapters have 4 times the tensile and yield strength and many times the fatigue resistance of our competitor's 7075-T6 bodies at 400F. No more welding bosses to induction tubes. Please note, these parts are only sold with complete SDS system orders.

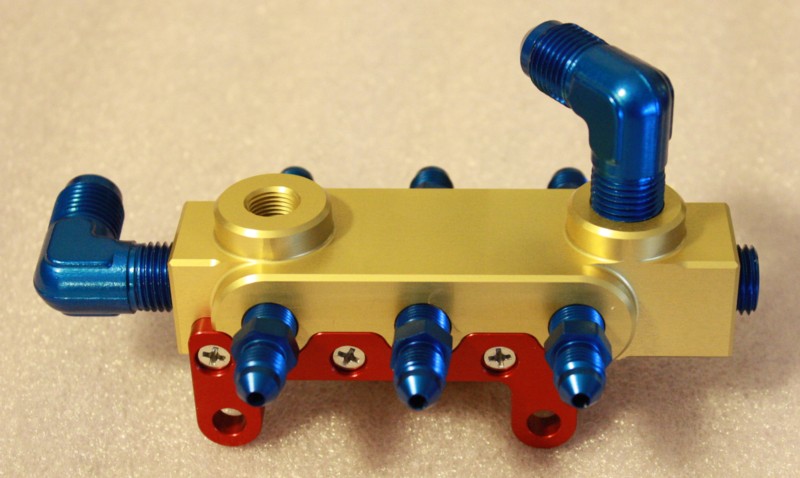

Center mount fuel block for 6 cylinder Lycoming engines

Block mounts through these case bolt holes

Shown with -3 stainless braided lines connected

Baffle mount fuel block on a 540

SDS FAB mounting kit on a vertical induction 540 (Todd Johnson photo)

Dual fuel pump module mounted in an RV10

Dual root mount filter setup from Flightlines

https://www.youtube.com/watch?v=jHp2poqf_Bs

Video of Bill Beaton's supercharged IO-540 Rocket running SDS EM-5 and CPI

Bill Beaton's IO-540 on the test stand at Aerosport

Bill's Supercharged Rocket. World's fastest Rocket- 282 mph at Reno 2016

SDS EM-5 in Bill's Supercharged Rocket

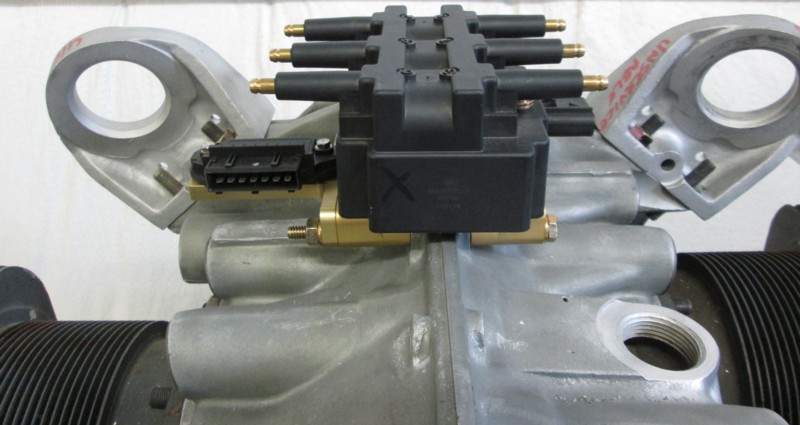

540 top coil mount

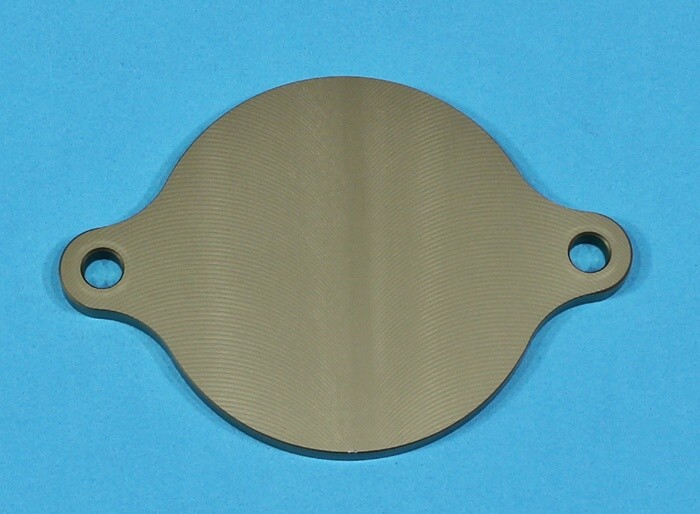

Dual Mag cover solution plugs mag hole and mount one coil pack.

For Dualmag Lycomings, we have a special cover plate and spigot to plug the mag and oiling holes. Note that not all engines have the mag oiling hole. Ones that don't, can use our regular cover plate and coil bracket to mount one coil there as shown above. There are 3 different shaft sizes for the spigot, please measure yours before ordering.

Tefzel wiring harnesses

Dual coil mount for RV10 aircraft. This mounts to the top of the engine mount. Comes with mounting hardware.

Many thanks to Ashley Miller for the design and these photos

Standard and Optional Features

SDS offers the following features not found on other vendor kits:

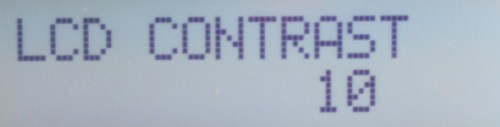

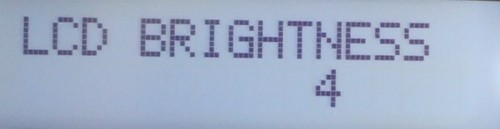

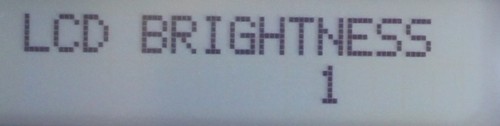

The new programmers feature a higher temperature spec LCD (-20 to +70C) and adjustable contrast and brightness control. The brightness control was added per customer requests for night flying comfort.

Here we see the contrast control screen- 16 settings

This shows the old defaut level brightness

This is a medium level brightness

This is a low level setting and the 0 setting is a bit lower than this.

Fuel pressure regulator mounting

Magneto cover. Install without gasket, just use RTV.

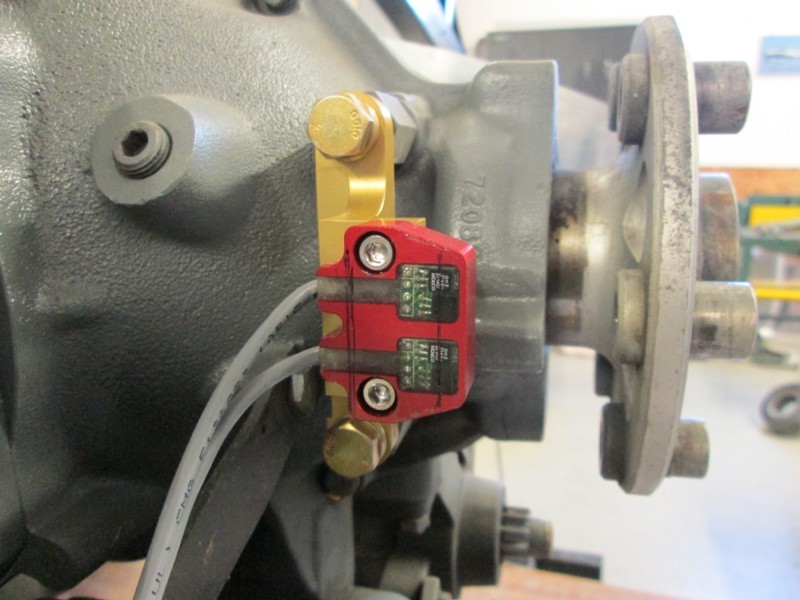

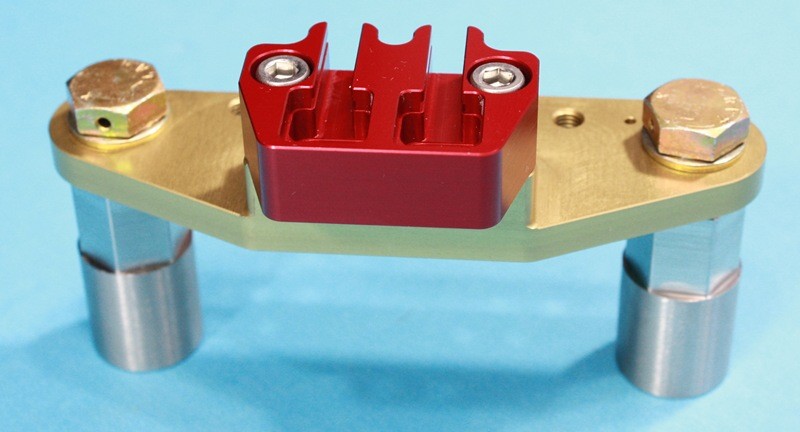

Hall sensor mount and dual Hall sensor in place

Weld-in bosses for race applications and engines without the 1/8 NPT injector holes in the heads

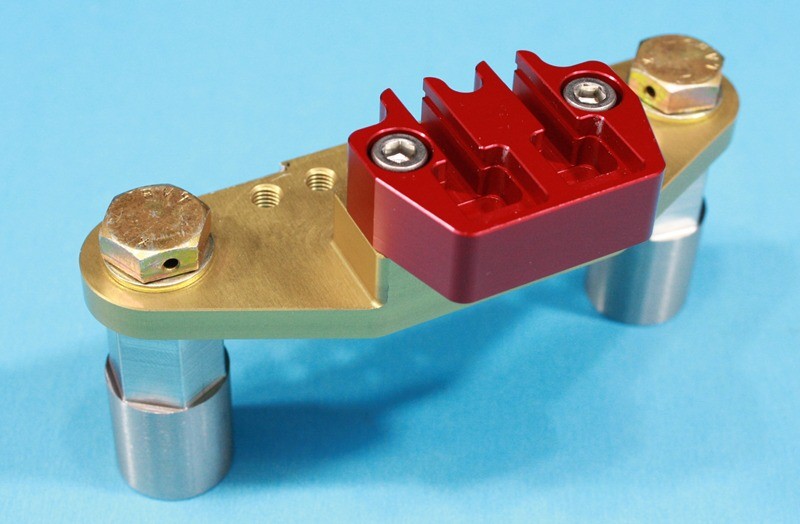

Photos of 3.50 inch bolt spacing Hall mount

3.25 inch bolt spacing Hall mount. Note mounts have threaded holes to bolt cable protection hardware to.

Please check the center to center front crankcase bolt distance. Some measure 3.25 inches, others 3.50 inches. We need to know this to send you the correct Hall sensor mount.

Billet 80mm throttle body to replace Bendix RSA-10 and AFP FM-300 servos when converting to EFI. Horizontal mounting.

Air horn accepts 3.5 inch SCAT hose, 3.5 inch ID K&N filters or 3.5 inch ID Silicone hose couplers. 6061T6 construction, stainless steel shaft, 7075T6 throttle arm, brass butterfly, accepts OEM Bosch TPS, O-ring sealed air horn to body and flange to sump. Under 2 pounds and only 3.625 inches high. Integral throttle stop. Stainless hardware. Barb vacuum fittings for MAP and fuel pressure takeoffs.

Rear coil pack mount for 540 engines

Spark plugs and adapters for long reach Angle Valve Lycomings (IO-390/ 580)

MSD Plug Wires and Boots

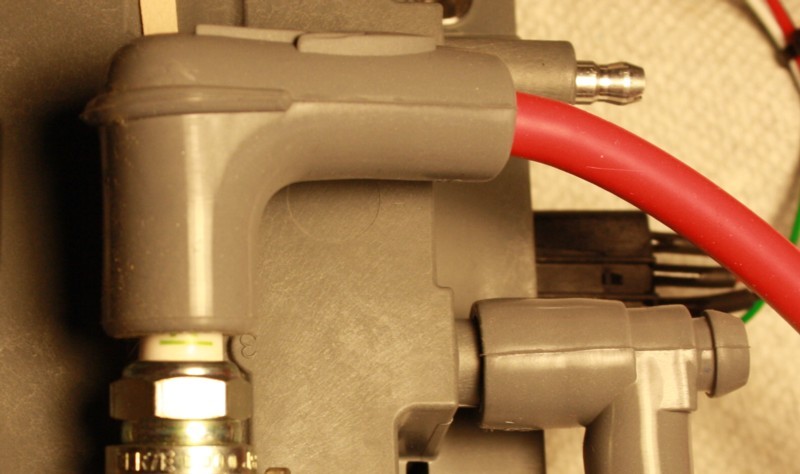

Be sure you push the plug and coil boots all the way down to engage the terminals fully. There should be about a 1/8 inch gap as shown in the photo below

Magneto Parts to Remove on 6 Cylinder Lycoming Engines

Exploded view of magneto parts on Lycoming 540 engines: 540magparts.pdf

When replacing the mags on 6 cylinder Lycoming engines, be sure to remove the gear/ cup (6), cush drive (2) and pilot bearing (7) as shown above. Be very careful not to drop any of the parts into the sump! The extension housing (4) may be removed or left in place as desired

Website: aerosportpower.com

Ly-Con Rebuilding Co.

8231 W. Doe Ave.

Visalia, CA 93291

(559) 651-1070

(559) 651-3212 Fax

Email: john@lycon.com

Website: www.lycon.com Lycoming EFI