This article is intended to provide additional information for universities and colleges preparing cars for the annual FSAE competition in Detroit.

System Choices

We make 2 systems applicable for the 600cc, 4 cylinder motorcycle engines used by most teams. The D system is the choice if you plan to run the factory ignition system and require only the fuel injection control. The F system is the choice if you want complete fuel and ignition control. This is more important on turbocharged entries where ignition timing will likley be much different from the factory settings. The D has the advantages of lower cost and easier hookup and programming. The F gives more control but can be much more time consuming to install, especially the Hall sensor and crank magnets.

Both systems are available in either the standard 9750 rpm version or a 15,000 rpm version. Programming points are 250 apart on the 9750 version and 400 apart on the 15,000 one. You should specify which one is required. Be aware that with the mandated air restrictor in place, the engine may not make peak power over 9000 rpm.

Temperature sensors may be the standard 3/8 NPT GM ones which can be quite large for a small engine or the alternate 1/8 NPT ones that we offer. Most teams choose the smaller ones. You can order Celcius or Fahrenheit calibration on your system.

We will custom make your wiring and injector harnesses to whatever lengths that you require. We do recommend trying to mount the ECU 3 feet from the coils or spark plugs and wires. Some teams are mounting the ECU up front near the dash which often requires extra length on the main harness. Please specify the required length here. Standard harnesses are 6 feet to the engine sensors. Injector harnesses are supplied to your specs as well. We need to know the distance or spacing between each injector.

MAP or TPS?

SDS uses either throttle angle (TP) or manifold pressure (MAP) plus rpm to calculate engine airflow. MAP sensors are required on all system which use forced induction (turbo or supercharging). On naturally aspirated engines (atmo) engines, either MAP or TP load sensing can be used. MAP sensing gives you automatic altitude and barometric compensation, TP does not. TP systems can be easily adjusted to a different elevation with the manual mixture knob provided in each system. With the mandated FSAE airflow restrictor in place, there will be a point at full throttle where the manifold pressure in the intake plenum starts to drop. This can make programming of a MAP system more difficult on an atmo engine. With both systems, rpm fuel values will have to be decreased at high rpm to reduce the fuel flow as airflow drops off. TP systems are less influenced by pressure fluctuations that can affect MAP sensors and also by radical camshaft profiles. Both systems have worked well when properly programmed. Your ECU can be quickly switched from one method to the other by you if you wish to experiment.

Throttle Bodies

Most teams are using a single throttle plate and a plenum manifold. With the required restrictor, there is little sense in using a massive throttle body. The best source for 40 to 50mm TBs is the wrecking yard. Lots of Japanese cars from the '80s had nicely made, small TB's. If you can find one with a 3 wire, potentiometer type TPS, it can be used with our system. Otherwise, another TPS will have to be fitted. Most cars after 1985 have potentiomter type TPSs.

Injectors

Most FSAE engines are producing under 75 hp so you don't need very large injectors here. The smallest that we sell are 235cc/min. These are adequate for up to 170 hp on a 4 cylinder and will work. The smallest automotive ones available are 150 - 180ccs/min. but these can be hard to locate. Always get used injectors flow tested and matched before using them or you will not get good results. EFI demands that all injectors flow the same amount of fuel. We recommend low impedance (1.7-3 ohms) injectors for use on these small engines as they give better idle control than high impedance ones (12-16 ohm).

Fuel Pumps/Regulators

Most automotive pumps are a bit on the large side for 75 hp. Pumps are either of the in-tank or external variety. The smallest pump that we sell is good for about 300 hp and draws about 5 amps. Used pumps are OK if you check flow rate and pressure delivery BEFORE installing on the vehicle. Fuel pressure regulators are usually mounted on or near the fuel rail. These hold the fuel pressure at a constant value or differential. The wrecking yard is the best source for these. Again, Japanese cars seem to be the best source for simple and reliable ones. Nissan and Toyota ones are popular. They are available in both external and rail mounted styles.

Other Tips

It is a very good idea to have a charging system on your car. This holds the battery voltage at a constant value for consistent results. Our system does not require an O2 sensor for system operation. If you want to experiment with closed loop running, then you will need one. We highly recommend a mixture meter which hooks up to an O2 sensor and reads out your air/fuel ratio. These will save you a lot of tuning time and possibly your engine. You will have to fabricate you own fuel rail, intake manifold and restrictor. We do sell some aluminum injector bosses which might be useable on your manifold to mount injectors. For some basic information on fabricating plenum type manifolds, check out the Tech article as well as the one on our Aircraft pages. If you want to be successful in Detroit, the best advice is to finish the car early and TEST, TEST, TEST before you go to the competition. If you plan to tune at the event and sort out chassis and drivetrain problems there, you will probably not finish well. Preparation is everything in racing. If you require any more information please feel free to E-mail us.

Payment

We offer all legitimate FSAE and university engine projects a 15% discount on systems and parts. Pre-payment can be made by wire transfer, university check or credit card. We will now accept POs only if checks will be issued within 14 days of receipt of goods. Otherwise, the order must be pre-paid. We can fax or E-mail a complete quote to your purchasing department.

We are happy to publish stories and photos of FSAE efforts on this page below. Send us your photos in JPEG format with your E-mailed story.

09/21/00 This is the 2000 Formula SAE entry from the University of Chicoutimi 2000.

Thanks to Pascal Gauthier for the details and photos

The frame is constructed from 1020 steel tubing. The body work is Fiberglass. The front suspension consists of 4130 unequal length, double A-arms, anti-roll bar, RockShox coilover spring & RockShox dampers.

The wheelbase is 1600mm. Weight is 260 Kg and weight distribution is 45:55. Wheels are Keizer, tires are Hoosier. Engine is a naturally aspirated, 1995 Yamaha YZF 600cc equipped with an SDS EM-3 4F engine management system. A 6 speed, manually shifted transmission and limited slip differential are used. Calipers are Wilwood Dynalite single carbon composite.

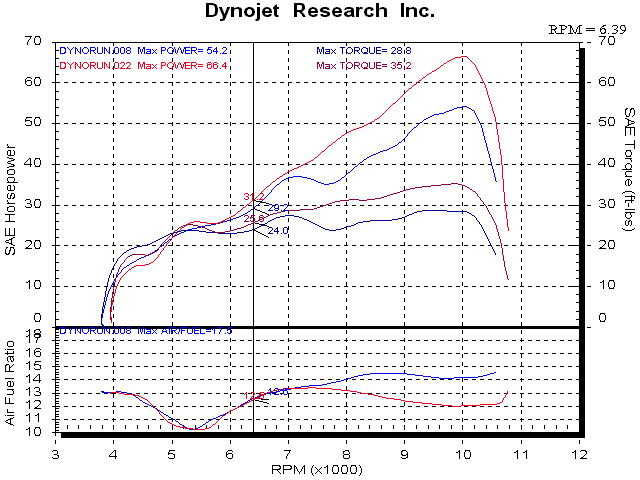

This car was built during the third year of formula SAE UQAC. It's the first time that an injection system worked on the car. Pascal said "When I started the engine for the first time with SDS system, the engine ran really well. I just changed some values in the fuel parameters and the engine ran really well. When I put the car on the dyno, we obtained 52 HP and after three runs, we got approximately 66 HP. It's a gain of 21%. SDS made it really easy to tune the engine on the dyno. In 2000-2001, our team will work to develop a chassis in aluminium 6061-T6 with heat treatment and anodizing. And we will try to invent a new kind of electric shifter. If it's possible, we will build the suspension in Duralcan (alloy of Ceramic and Aluminium). We plan keep the same kind of injection on a new engine (Honda CBR F3 600CC). Also, the service to the customer was really good from SDS."

08/17/00 This is the 2000 Formula SAE entry from the University of Toronto.

The car is powered by a naturally aspirated Honda CBR600F4 engine. The engine internals are stock except for a milled head. A two quart Accusump keeps the engine lubed through the twisties.

An SDS EM2 4F controls both fuel and spark. To save weight the ECU has been modified to drive the stock coil-on-plugs. The engine is smooth straight off idle, power comes on at 6500 rpms and the engine pulls hard until redline at 14000 rpms.

The engine breathes through a custom-made intake manifold. Injection hardware includes 155cc Corolla injectors, rail and regulator. A custom-made equal length header and muffler complete the engine package.

The car won the Dynojet High Horsepower Award at the 2000 Formual SAE competition by putting down 80.1 HP to the rollers, while breathing through the mandatory 20mm intake restrictor.

Fox 3 way adjustable shocks mounted inboard help through the turns, as well as adjustable antiroll bars front and rear. Hoosier 20x6 slicks on Monocoque 13x7 rims complete the package. A Zexel torsen differential splits the power to the rear wheels. The car also features disk brakes in the front and a single brake disk, mounted on the differential, in the rear.

Results include a 2nd place finish at Formula Student in the UK and 8th place finish at Formula SAE in the US.

Dec. '99 FSAE Feature

This is the FSAE car from Sherbrooke University in Quebec. It is powered by a modified Honda F2-CBR 600 engine. The engine fatures a custom header and intake manifold. With the mandated 20mm restrictor in place, the engine is currently producing 70 hp at 12,000 rpm on the dyno. Engine management is handled by an SDS EM-2F direct fire system. The chassis is a steel tubing space frame and the cars weighs under 600 lbs.

Here is a photo of the Ryerson 2001 FSAE entry. It has a 70 inch wheel base. The front section of the frame consists of a mild steel substructure and bonded and riveted aluminum honeycomb panels (1in thick). The rear section is all 1" chromoly. The car runs a stock Yamaha R6 motor with the stock igntion and the SDS 4D system. The suspension consists of un-equal length a-arms fornt and rear, with pull rod actuation, and Dynamic Suspensions coil-over dampers. The drive train consists of a chain driven, Torsen differential, driving the wheels via VW cv joints and custom drive shafts. The brakes consist of Wilwood calipers and laser cut rotors front and rear. The rear has a single disc acting through the differential.

Overall, the car weighs in at 550 lbs. This is mostly due to over-sized parts to ensure durability. The weight distribution is pretty good at about 45:55 front to rear.