Superior Design= Superior Performance

SDS- The Fastest EFI in the World

Last Update April 6/24

Reasons Why You Might Consider SDS Over Other Vendors

1. Unmatched experience- 30 years and over 11,000 electronic controllers delivered, 2500 for aviation. We've supplied more programmable ECUs for Experimental aviation than all other brands combined.

2. Unmatched reliability proven in over 23 million hours and 1 million flight hours

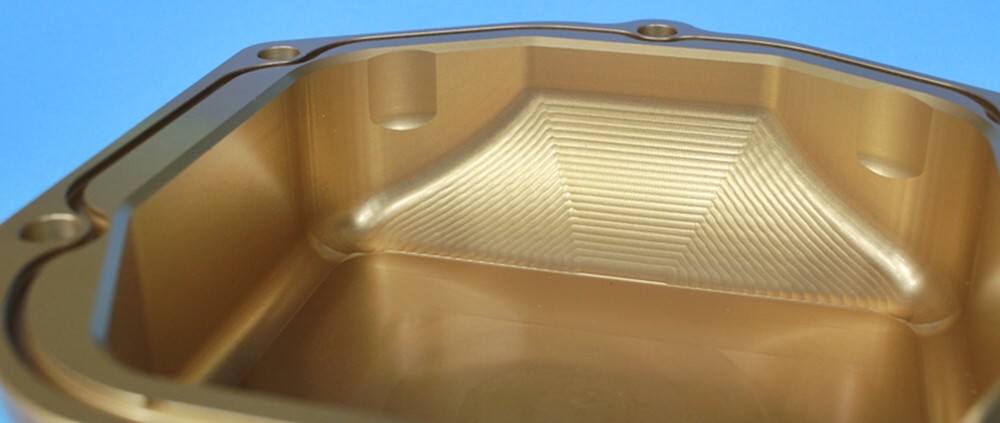

3. Best quality CNC'd parts made from the proper materials for each application

4. Best tech support in the industry

5. We fly what we sell

6. No sales hype and BS- just the facts so you can make an informed buying decision

7. Light weight

8. Logical, simple design and programming

9. Wiring is custom made to your length and termination requirements

10. Often several choices for mounting hardware to best suit your needs

11. New 6th Gen ECU is the most capable user programmable ECU ever offered for Experimental aviation

12. 3 Reno Sport Class Gold championships won with SDS EFI

13. Lots of information about our products and accomplishments on our website and YouTube channel. We also directly engage people and answer questions on the popular VAF forum

14. Innovation. We've introduced over 120 new hardware and software improvements and features since 2015 with more new features on the EM-6

15. We actively encourage feedback from customers to help improve our products and guide the development and features of future products. If you have issues, we want to hear about them and solve them

16. We actually publish Service Bulletins on our website when we see a parts problem or trend which could affect safety.

Our Design1 programmer was heavily influenced and shaped by customer feedback and has proven to be extermely popular for it's new look, features and compact shape which integrates well with modern glass panels

Information

Our website and YouTube channel provide actual information on our products. We have lots of sub-pages to break down content for specific topics and engines, prices and plenty of big photos of actual SDS installations to help you visualize how it's all put together. Conversely, the competitor's website has mostly hype and almost no useful information published. Our YouTube channel has many videos on how-to, hardware, how things are made, programming, Reno race videos and flying SDS products. With over 6800,000 collective views, this is a useful and popular format to inform people about SDS products.

To see all the videos on our YouTube channel, click here: https://www.youtube.com/channel/UCiyBZlgDHg2GvQfelECCGoQ

Better Design and Materials

Our competitor says "We only use the best parts and materials available". Let's examine that statement.

Here's an example of SDS vs. the competitor's Brand X hardware. On the left is is the SDS billet throttle body specifically designed for Lycoming engines. On the right is the Brand X heavy, cast automotive TB with cast adapter. Our TB weighs 412 grams, their's weighs 1630 grams. We use an O-ring to seal all of our throttle bodies to the intake manifold. The competitor still uses paper gaskets. We use stainless and aircraft AN hardware fasteners while you can see the rusty, unplated automotive hardware used on their setup. This Brand X hardware was sent to us by a client in Australia, unused, to be replaced by SDS hardware, wiring and proper, port mounted injectors.

Brand X throttle linkage failure at only 40 hours

Our complete line of billet throttle bodies, from left to right, 80mm, 60mm, 45mm, 40mm.

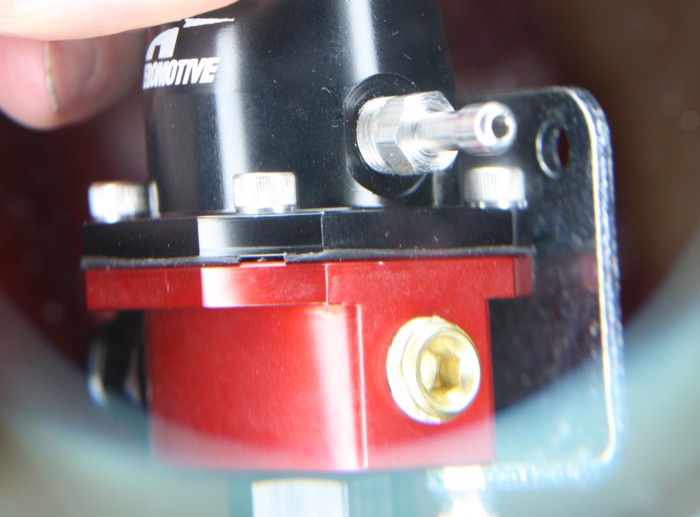

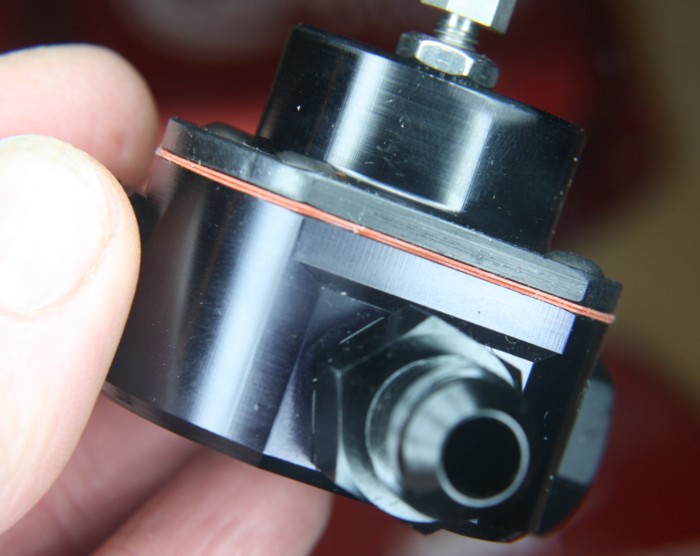

Brand X uses a less expensive fuel pressure regulator with single diaphragm which has had multiple ball and seat failures

Here are some photos of the Brand X regulator failures

We use this Borla regulator with a twin diaphragm. This is a flight critical part. We feel only the best will do here.

Brand X cheap, non-servicable fuel filters

SDS supplies quality billet, servicable filters

The competitor mounted the engine temperature sensor in the fuel pump cover originally because it was easy but that made it slow to react to warmup conditions for enrichment. We mount our sensor where it belongs- in the cylinder head.

Our billet flywheels won't crack or be severely out of balance in contrast to other lightweight flywheels on the market from our competitors

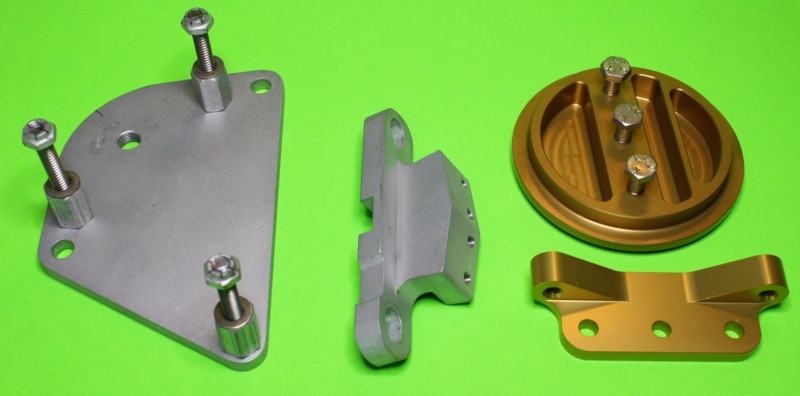

We can supply these with magnets pre-mounted or our EFI kits come with a CNC'd drilling jig so you can install the magnets on your own flywheel. No need to ship a flywheel out to be drilled as Brand X requires.

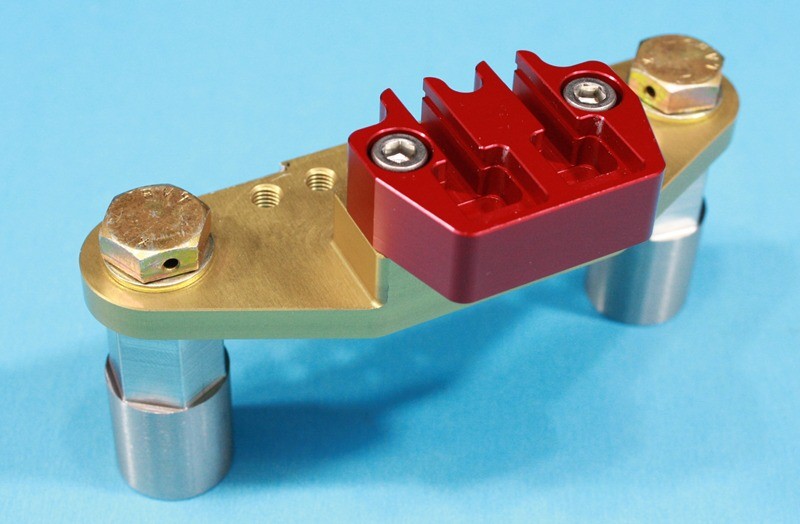

SDS fuel pump module has rigid frame so pumps are not loaded when mounted as in the competitor's design. Immaculate machining and anodized finish. We use straight through fuel fittings and stainless hardware. Competitor uses banjo fittings. One competitor in Norway also bought our module and then copied it exactly. I have the email where he admitted that he copied it and asked for forgiveness for his deceit after saying it was only for his own personal aircraft. Their original design was so crappy, he ditched it for ours. We cut him off all further purchases immediately and removed the web page that we specifically created to help him sell our EFI systems. The owner of this company also stated in 2020 on a Facebook forum "SDS is so far behind and they stole all our Rotax/Jabiru/Vw EFI kit components". Really? We were producing Rotax EFI kits back in 2008, years before any association with this guy, again supplying him with ECUs and other bits like Brand X. Our other Jabiru CNC'd parts look nothing like his- throttle body, adapter, injectors bosses (he copied our design here again, dating back to 2003). We never produced any CNC'd VW specific kit parts and still don't. Anyway, this Norwegian guy and the Brand X owner teamed up now. They make a nice pair. Both full of BS.

SDS crank sensor bracket above. In a feeble attempt to discredit our products, Brand X claims our parts are "poorly engineered" and "garbage". Really? On what basis? More sour grapes and made up nonsense, with no facts ever presented to support their statements.

Brand X coil mount and crank sensor bracket left. Note scabby looking bare surface (what better way to promote corrosion!) and the lack of any radius to reduce stress risers. SDS parts right, anodized for long lasting corrosion/ scratch resistance and appearance. Note radius at junctions- the proper way to machine parts. Notice our parts look nothing like their's, which they claimed we copied. Our 3 machining partners have a combined 75 years of CNCing experience.

Here are some more examples of SDS parts

So, who's parts actually look like garbage?

It's amazing how many Brand X buyers ask us to sell them parts of our kit because they don't like the design or the poor quality of hardware supplied with the Brand X kits. Our policy is to use the parts we machine for our own kit production. We don't want the liability to supply parts for some Frankenstein system.

Wiring

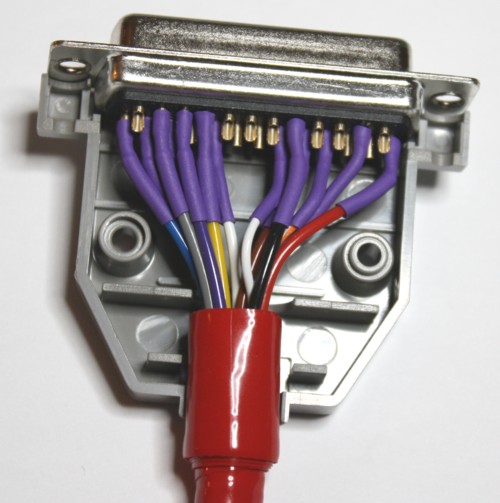

As the competitor trashes the DYNO TEST wiring SDS supplied AS REQUESTED (nice false spin there) to engine building shops in some YouTube vids, let's compare what we supply vs. what they supply for the actual flight rated hardware.

Brand X wiring (left) doesn't use heat shrink strain relief on their D Sub wiring or proper strain relief at the hood capture. SDS (right) has both.

Brand X main harness on new system install 2020. Note cold solder joints and main CPU wire which just fell off due to defective workmanship. ECU wouldn't power up on initial attempt. Good thing this happened on the ground.

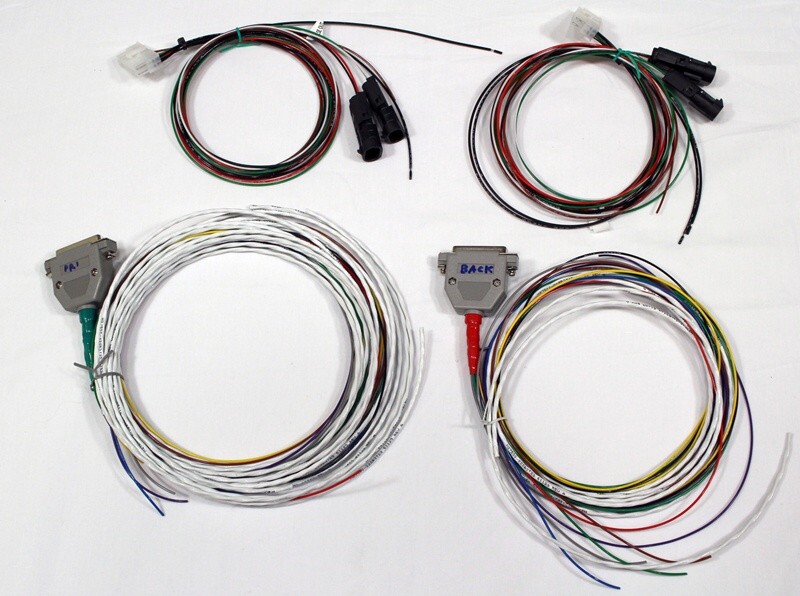

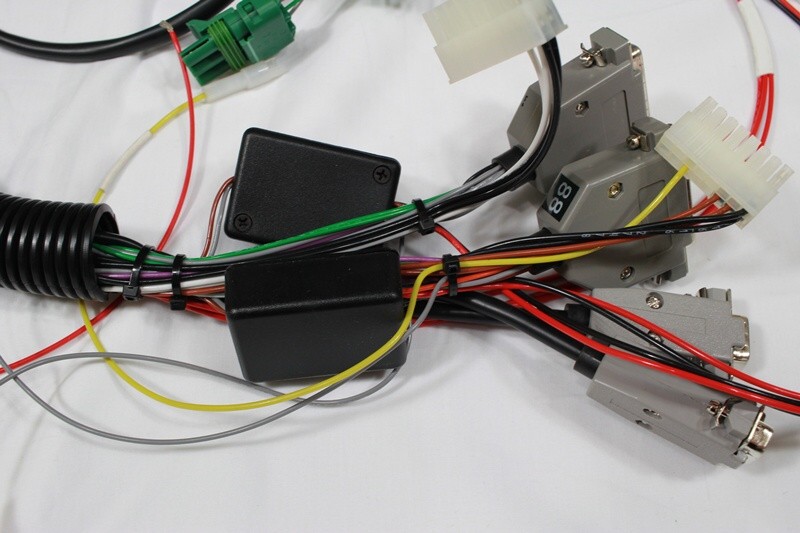

SDS supplied Tefzel wiring since 2016. Note clean, flexible, small diameter design to fit easily through your firewall without a big hole. We tailor lengths to your specs and can leave unterminated as shown here, pinned only or terminated as you wish. Individual cables for each sensor allows for easy routing and you have the ability to use a proper fire rated stainless penetration.

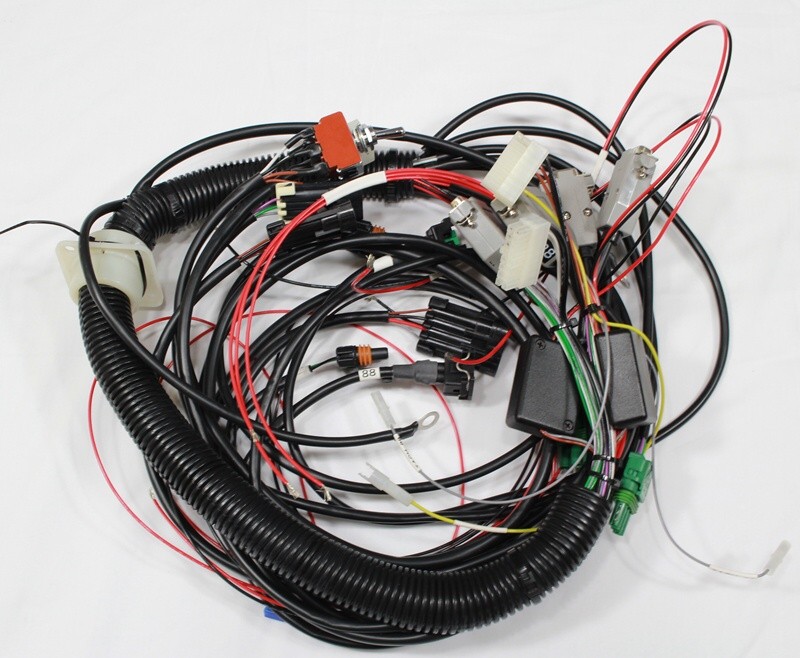

Brand X supplied harness 2013-2017. One big mass of stiff wires, hard to route. Note automotive split plastic sheathing and huge size, requiring a 1.5 inch hole in the firewall. One size fits all apparently which wasn't popular with clients who talked to us and often had to lengthen wires.

Brand X harness top, SDS harnesses lower. Note size difference. Note the massive non-fireproof nylon grommet installed. This is for aviation apparently. Their new system uses plastic Cannon plugs at the firewall. An improvement for installation but not fire rated. More connections mean more potential places for failure. If it's not there, it can't fail we say. Our wiring is 30% lighter than the competitor's.

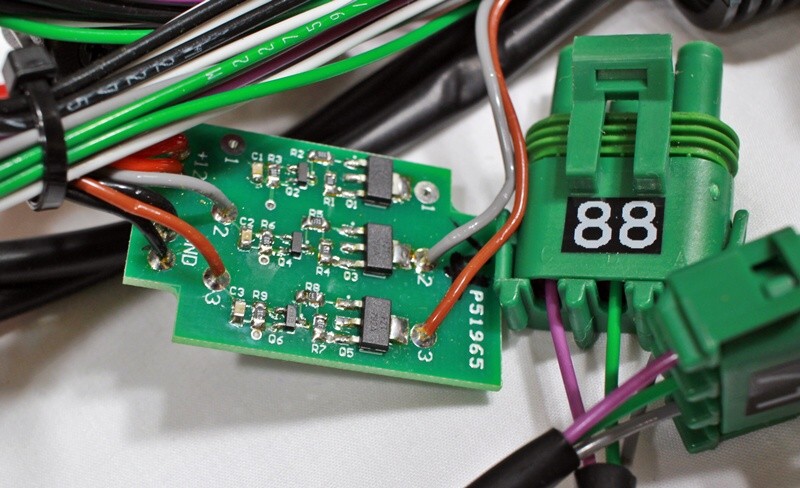

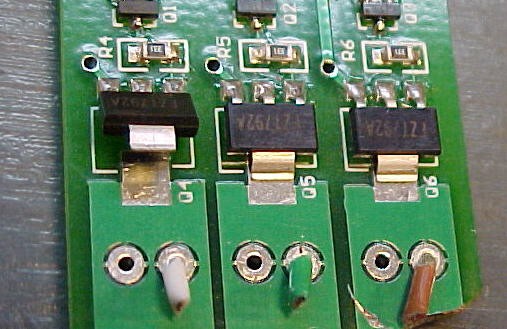

Competitor jury rigged his own coil driver boxes onto his harnesses instead of using the clean and reliable internal ECU drivers that SDS offered since 2014.

Note the sketchy hand soldering on the components on this one.

Poor soldering and overheating resulted in several failures of solder joints and no ignition channel. Note the minimal solder on this failed one where the tab lifted off the pad.

See video on how our ECU boards are manufactured to ISO 9001 standards:

SDS replaced the Brand X wiring and coil drivers for many clients who were unhappy with the mess they were originally supplied. We also updated software and gave them SDS features like accurate internal digital fuel flow (competitor tacked on another external box which wasn't accurate), individual cylinder fuel trim and dual cable programmers.

The Brand X terminated harnesses limit mounting flexibility of components like the ECUs in some aircraft. SDS allows total flexibility with unterminated, custom length harnesses which can be tailored to fit everything from a J3 to a Cozy. We build wiring for YOUR airplane, not generic "one size fits all".

Countering BS Marketing and Disinformation

Bullshit marketing is a strategy of making false or misleading statements which cannot be backed up by any facts or demonstration. These false statements are carefully worded to make the product sound superior to customers who don't undertstand the technicalities involved. BS is BS, no matter how it's disguised in flowery terms. This page tackles the disinformation put forth by one competitor.

"If you can't dazzle them with brilliance, baffle them with bullshit."

W.C. Fields

Who Was First?

In an attempt to re-write historical fact, Brand X in 2019 claimed to be producing the first, purpose-built EFI system for Experimental aviation. Not true. To put credit where it's due, Precision Airmotive introduced the Eagle EMS way back in 2005. SDS has been supplying the Experimental aviation market since 1995 and we sold our first Lycoming system in 1997- over 2 decades before this one competitor started making their own electronics. This competitor also said SDS copied their designs! How is that even possible if we were producing products decades before they even made their first parts? You can see our hardware and electronics is of different design and quality. They have copied every innovation we developed years before and tried to take credit for being first on their new system

Brand X claims they were producing EFI systems for Lycoming engines back in 2008. One look with Wayback Machine shows their website had no content in 2008 so that is also not true. They didn't buy the first test ECU from us until 2011 and it was almost 2 years after that before production parts were ready for their kits. Another deception on their part in an attempt to re-write historical fact. From 2013-2017 they simply rebranded our SDS ECUs and programmers with their name. They didn't produce anything significant themselves outside of a few brackets and mounts. The biggest problem with these guys is they had no experience and no track record in designing and producing ECUs for aircraft prior to 2019. That looked bad, so they make up BS stories to try to make themselves look good. Their whole business is built on bullshit and disinformation. We'll take them to task here with the facts.

Brand X copied our ECU connector layout from the 1997 EM-2 era- 20 years later.

Who Supplied Those Hundreds of "Legacy" ECUs?

Brand X claims that "they supplied over 600 ECUs for aviation" is patently false. Every one of those ECUs from 2013 to 2017 was manufactured by SDS, not by them. They had zero experience manufacturing workable ECUs until 2018 in fact. Just putting your decal on an SDS manufactured ECU doesn't make it "your" ECU.

The SDS made EM-5 ECUs sold by our competitor and simply rebranded with their name (a fact they tried their best to hide for years) from 2013 to 2017, used a 16 bit processor, not an 8 bit as they have stated. This microprocessor was first offered in 2000, not the 1990s as they have repeatedly stated. Because of our compact code, the 16 bit CPU executes main loop in 209 millionths of a second which is more than fast enough to track any relatively glacial changes in sensor inputs on a slow turning Lycoming engine. This design came from automotive motorsports where engines have quadruple the rev range and quadruple the rate of acceleration compared to Lycomings. The same processor family was used on several other well known programmable 3D EFI systems, proving it was more than powerful enough for the task here. They tout their 32 bit processor as being far superior. Might be if you run tens of thousands of lines of bloated code but we don't have to with our compact code. Compact code executes faster, so you don't need a super fast CPU. More code REQUIRES a faster CPU to execute it in the same amount of time.

SDS Pioneered Features and Brand X Hypocrisy

SDS pioneered the first Experimental aviation, individual cylinder fuel trimming feature back in 2016. This allows the user to equalize air/ fuel ratios in each cylinder based on EGT data in flight, in only a few seconds. Brand X told people they didn't need this feature back in 2016 but have now copied our idea and added it to their own system.

With regards to "their" "new" features, SDS has had features like closed loop since 1995, knock control 1996, aviation programmer 2006, lean warning/ auto enrichment 2007, MAP averaging/ interpolation and full data logging 2014, dual access programmer 2015, individual cylinder trim, internal digital fuel flow, baro, LOP ignition advance and cylinder mounted injectors 2016. These features are hardly new, we pioneered many of them long ago in this market and have sold over 2500 ECUs for aviation as of March 2024.

We offered our then dealer, now Brand X competitor, these advanced features back in 2016 but he decided not to offer them to his clients, instead selling them dumbed down units and telling them they didn't need these features. Yet upon introduction of his new system, he had incorporated all of them! Later when his earlier clients found out that they had not been offered the fuel trim, internal fuel flow or dual programmer features when he could have, were rather unhappy. Can you imagine forcing clients to unplug the single programmer cable and plug it into the 2nd ECU in order to program it each time? Ridiculous.

These guys call themselves experts in the field- hardly. They had to call on outside help to design their new system because they had no experience designing ECUs or interfaces. By contrast, SDS designs all hardware and writes all software entirely in-house.

Injector Mounting

Brand X claimed better throttle response, idle and starting over "Legacy" ECUs (their word for SDS suplied ECUs). More false information. Unlike SDS EFI aviation kits, which fitted the injectors to spray towards the valves as EVERY automotive OEM (and Lycoming) does, our competitor, incredibly, faced them to spray AWAY from the valve and kept doing it years after we told them this was causing their cold starting and throttle response issues. SDS kits had no such issues. We even took the time to write custom software for the competitor in an attempt to fix the throttle response issues reported by his customers. Our thousands of customers never had these issues with the injectors pointing the correct way.

Brand X famous "wrong way" mounted injectors which they touted as "superior". More nonsense.

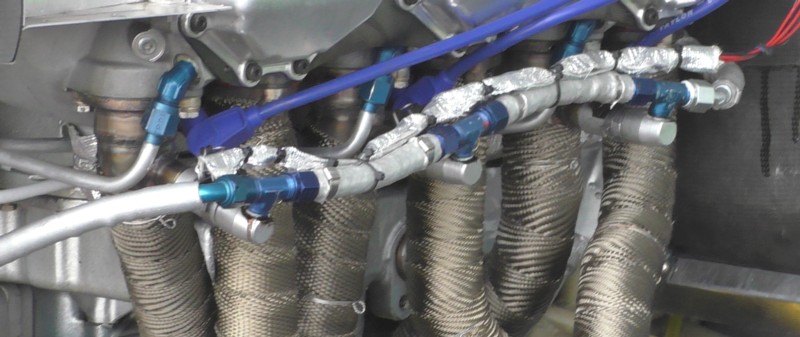

Competitor mounted their injectors the wrong way for years claiming this was better than all other EFI installations in the world where the injector faces towards the port. Resulted in inferior cold starting and throttle response. Their kludged hardware (notice those Oettinger type hose clamps) and rigid mechanical layout led to a fuel fire (fortunately on the ground at that point) on one aircraft when things cracked open. The aircraft was saved and re-fitted with SDS hardware to race at Reno 2018, 2 weeks after the incident.

Notice proximity of injectors and fuel rails to the exhaust pipes on the latest Brand X setups. According to Brand X, this results in cooler temperatures...

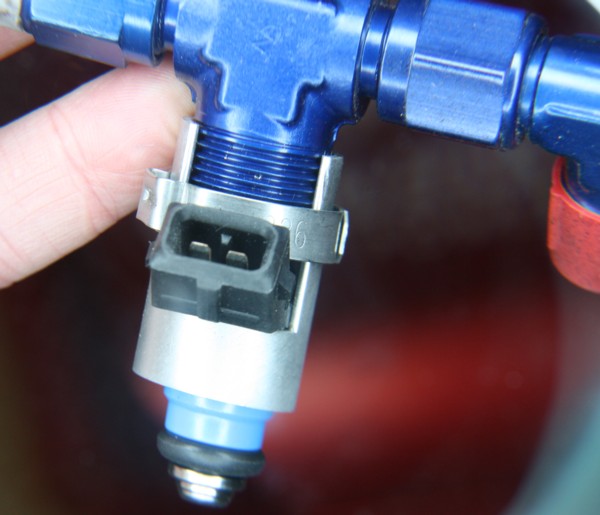

Closeup of competitor injector mount system with thin walled aluminum capture having sharp edged cuts in them (stress risers)and using crimp type hose clamps to hold injectors to fuel manifolds.

2021 Brand X injector mount cracking, just where we predicted it would. No surprise with this poor design. These have failed multiple times resulting in engine fires and forced landing yet the poor design has never be changed and so service bulletin issued warning customers.

Our injector mount design with high strength adapter and narrow spray angle injector, positively bolted together, not kludged together with hose clamps.

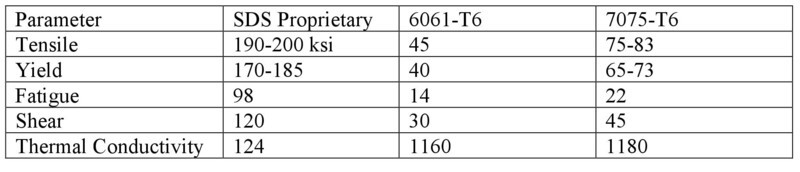

SDS uses a proprietary steel alloy with far superior strength and much lower thermal conductivity (see materials comparison chart below). Brand X uses an injector with a wide spray pattern resulting in the injector spray impinging on the ID of the bore vs. the injector that we use, having a narrow pattern to avoid this issue.

Their latest system copied our basic idea from 2016 to fit the injectors into cylinders. However instead of doing it in the factory injector ports on top as SDS (and Lycoming) does, they used the primer ports. They claim that this position results in cooler running for the injectors, however this actually results in much higher temperatures for the injectors. Their claims were proven false in testing by one of our clients who instrumented his installation with thermocouples in the injectors both above and below. This testing with thermocouples on the injector housing showed a max temp of 174F after 10 minutes with the heads at about 280F on shutdown so the injectors don't get anywhere near as hot as the heads. In flight, where the engine spends most of its time, injector temps are 150-200F cooler with the top mount position as compared to in the primer port. Top mounting bathes the injectors in ambient air rather than air passing through the head finning and adjacent to the 1200F+ exhaust stacks with the primer port location. The competitor also used aluminum alloys initially with low fatigue strength and high thermal conductivity (transferring even more heat from the hot head into the injector) for the mounts in this highly stressed design. They simply didn't know any better because they have minimal knowledge about materials and metallurgy. Later they switched to stainless steel after people told them how scary aluminum was in this application. Even stainless steel is far inferior in strength to the alloy that SDS uses.

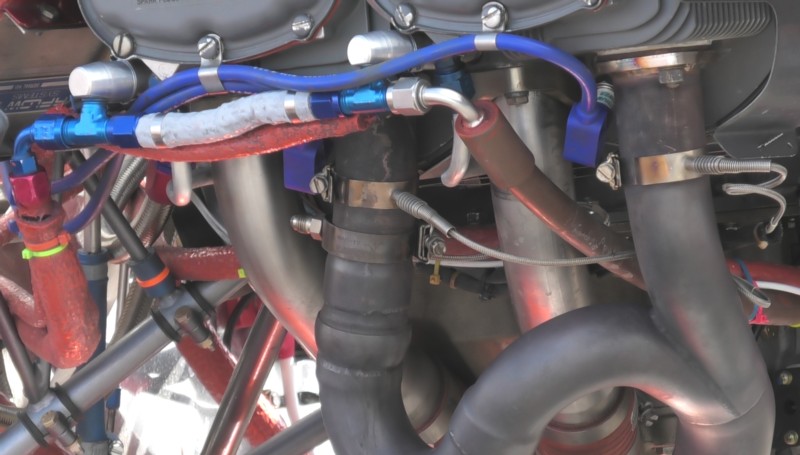

Competitor's new setup. Notice the rat's nest of plumbing, clamps and fittings being bathed in hot cooling air and adjacent to the hot exhaust. They interfere with the oil drainback fittings and won't clear the cowlings on some aircraft.

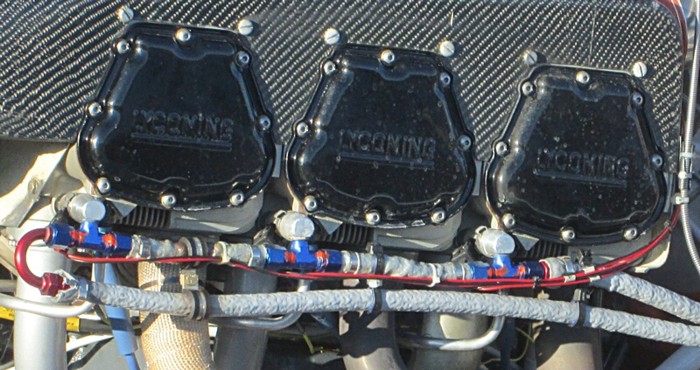

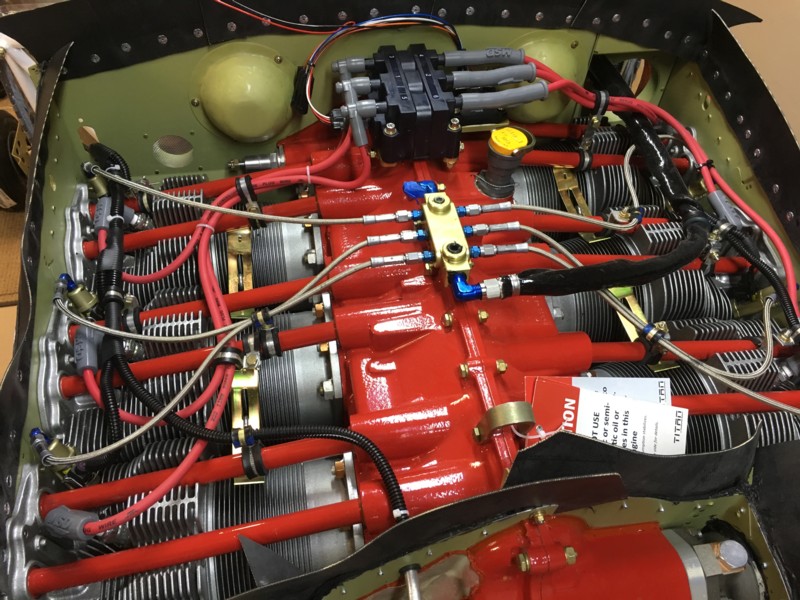

Clean SDS installation places the injectors on top in cool air and away from the hot exhaust stacks. Uncluttered and easy access for inspection.

Why has Brand X has abandoned their "superior" backwards facing injectors and mounted them to face towards the port now after telling people for years that backwards was superior? More bullshit.

6 Cylinder Coils

Brand X uses three 4 cylinder coil packs on their 6 cylinder systems. This creates a mess with the dual ECUs as half of one coil pack is driven by each ECU, making it difficult to verify coil function on runup. SDS logically uses two 6 cylinder coil packs with one ECU controlling each, one for top plugs usually and one for bottom plugs. This is cleaner and easier to understand and allows an easy ignition check by allowing you to turn coil power off on each coil pack to verify operation.

Injector Firing Strategies

Brand X says their semi sequential injection is just like your modern car and offers all the benfits of sequential. More BS. Modern cars have FULL sequential injection using a cam sensor (Lycomings don't have this sensor). Semi sequential offers no tangible benefits over the batch or independently fired, non-timed injection strategies that SDS uses. Semi sequential does not offer the slight part throttle or emission advantages of full sequential injection. This is because injector flow is not timed to valve opening as in full sequential systems. No power gains are seen with sequential or semi sequential over batch fired systems. This has been extensively proven on many dynos. In fact, even full sequential injection shows no gains in WOT, high rpm power over batch firing simply because there is not enough time at higher engine rpms and high MAP to inject the required fuel in the short time the valves are open so some fuel is injected on a closed valve anyway- just like any non-timed system. Sequential injection was developed for part throttle, low speed emissions and fuel economy improvements in the automotive world. These don't apply in the aviation environment. Semi sequential advantages over other non-timed injection strategies are therefore imagined, not reality. Yet another case of trying to promote their new product with more bullshit. SDS has no problem fueling or sparking Andy Findlay's Lancair to over 400 mph laps at Reno- something the competitor's "vastly superior" new system has never done.

"Vastly Superior ECU?"

On steady state applications like aircraft engines, the critical items for producing maximum power are the right amount of fuel, ignited at the right time by the ignition system. AFR and ignition timing in other words. A $4500 MoTec ECU won't make any more power under these conditions than a $300 Megasquirt ECU. BS and hype about spark energy and processor speed doesn't change this reality for the average stock aircraft engine. It all comes down to X injector pulse width and X ignition timing. SDS has proven at Reno to be able to fuel and ignite the most powerful Sport Class racers running very high manifold pressures (100+ inches) so stock engines present no issues. As such, the Brand X "vastly Superior" ECU isn't going to make any more power than an SDS ECU.

"Brown Outs"?

Brand X claims SDS ECUs are subject to "Brown Outs" when cranking which can cause broken starters. Since our ECUs function down to 7.3 volts and a good starter/ battery, cable system should maintain at least 9V during cranking, this isn't possible and is just more made up bullshit. With over 23 million hours collectively on our controllers, we have had no reports from our users of these things happening. We've personally started engines with SDS at -36C where the engine would only crank over at about 50-60 rpm and under 8 volts indicated. No kickback. It's highly doubtful that most starters would even turn the engine over at 7.3 volts.

Reno Racing

We race at Reno to improve our products and test them in a very demanding environment and have supplied complete systems since 2008.

While Brand X hyped their debut at Reno 2018 and made misleading, false and ridiculous claims, our results speak for themselves. SDS ECUs have won THREE Reno Gold Sport Class Championships, Brand X guys, ZERO. In fact, the airplanes fitted with their new "superior" system, didn't even qualify or start the races in 2018 because they had so many technical issues and Maydays during practice. SDS won Gold Sport Class in 2010, 2018 and 2019. In 2019, the SDS equipped Lancair of Andrew Findlay spanked all comers with the competitor's EFI by a large margin. In racing, we have an old saying- "When the flag drops, the bullshit stops"- never so apt as here. Our victory back in 2010 was the FIRST EVER for an EFI equipped aircraft at Reno. We are proud of this record and hope to add to it more.

Fact. Andy Findlay's 2 time Reno Sport Gold class winner has posted speeds 40-90 mph faster than the competitor's EFI equipped aircraft. All this, with our supposedly "inferior" EM-5 system. Andy's Lancair became the first Lancair to break 400mph at Reno and the first Lancair to average over 400mph for the whole race- 402mph in 2018, with one lap at 409 mph.

The Split

In 2015-2016, SDS developed many new features customers were asking for such as the dual access programmer (single programmer with dual cables could access 2 ECUs without unplugging a single cable), ECU internal digital fuel flow output to engine monitors (eliminated external boxes and mechanical flow transducers), PC data logging, individual cylinder fuel trim, LOP advance switch and a new ignition-only product. These were all offered to Brand X but he didn't want any of them for his customers so continued to sell them older, dumbed down versions. This attitude didn't make sense to us as he seemed disinterested in progressing these new product capabilities into the market. This was holding back our growth and as a result, we informed Brand X that we while we would continue to supply him with product, we'd start offering these new capabilities to our customers.

This didn't make brand X happy but what else could we do with this attitude? Brand X sales were falling well short of their projections at this point as well, so we had to take action to ensure our own business prospered. Brand X was only a re-seller for our products but seemed to think they controlled the direction of SDS. Nope. We'd never stopped supplying hundreds of ECUs to our own military and civilian customers during the time we supplied Brand X with ECUs, crank sensors and programmers. At this point, we suspected that Brand X might be working on their own ECUs, copy all of our latest innovations and planned to push SDS out of the market. This was the only reason we could think of why they wouldn't want the new capabilities for their customers. This was proven correct in fact. Their plan was replace the dumbed down SDS built systems they'd been selling their own customers for a couple years with their new "vastly superior" system (having the same features as what SDS had been selling since 2015/2016) and asking their customers for another couple thousand dollars to do it.

Brand X Sales and Marketing Approach

We encourage people considering EFI or EI systems to contact Brand X and listen to their sales pitch. They will probably spend more time ranting and trashing SDS than talking about their own products. This has been standard operating procedure for them since 2016... If SDS products were as terrible as these guys say, how have we become the largest supplier of programmable EFI/EI systems for Experimental aviation in the world and how have we remained in business 30 years? How do we keep beating them at Reno? Why is our business growing every year since 2016? Sounds like sour grapes coming from a desperate competitor trying to catch up to the leader in the industry.

Brand X "Comparison Chart"

A comparison of a comparison. Starting at the top of this erroneous document:

We highly suggest you look at this "comparison" on the Brand X website

Not sure what they mean by 1990s technology. Yes, we've been producing EFI systems since 1994 but the EM-6 offered today is nothing like the EM-1 offered in the '90s. The EM-6 was designed specifically for aviation (our main market for many years), building on our previous 29 years in the field. We've supplied over 2400 aviation ECUs in that time, many times more that what Brand X has who only started making ECUs in 2019.

While Brand X charged their customers to "upgrade" to their new ECU, SDS offered customers FREE EM-6 ECU boards dating back to 2018 purchases. Note Brand X never offered any of our new software features on the latter year EM-5s they sold to their customers so they could pretend to be the innovator rather than the follower they really are.

SDS hasn't used a 68HC processor since 2009. SDS has had interpolation for the same amount of time. We use a 16 bit processor, quite capable of doing everything required of it. Brand X tries to float the idea that only a 32 bit processor can do the job with "75X the processing power". What are the real advantages of that? It's never explained.

Brand X is so "superior" that you must shut the ECU down to reprogram ignition timing values- something other programmable ECUs haven't had to do since the early 1990s.

Brand X claims its fuel delivery is "timed" to valve opening being "semi sequential. It's either sequential or it's not. Sequential requires a cam sensor, but Brand X doesn't have one. Even true sequential injection shows no gains in power or fuel economy in the aviation environment anyway.

SDS is user reflashable. Doesn't require sending ECUs back for this as stated by Brand X.

SDS ECUs are designed for 14V operation. Will operate down to 7.3V and up to 16V. Will withstand up to 30V for over 1 minute. We've never suffered "brownouts"- more fantasies created by Brand X. Our units do require a voltage converter for use on 28V systems.

Brand X claims their 4 layer board is superior yet isn't even conformal coated like SDS. Several Brand X boards have suffered water damage as a result. SDS has RF filtering where deemed important.

SDS offers both card and PC logging capability. Manipulated and viewed with intuitive and easy to learn SDSDASH software.

SDS prefers to leave the programmer screen brightness control in the hands of the pilot rather than being automatic. Our design1 programmer which came out in 2019 offers a better fit for glass panels integrating nicely into the radio stack. Brand X uses the more dated 3 1/8 round type mounting.

Brand X states that SDS uses vinyl sleeved wiring. Nope, not since 2017 when we cut ties with you... Tefzel on customer stuff since then. Brand X firewall connectors are not fire proof- presenting a real hazard in the event of a fire. SDS harnesses are custom tailored to your installation and terminated on one end. No cookie cutter harnesses like Brand X. We also don't have wires fall off due to poor soldering like Brand X. (see the photo above).

SDS has had dual redundant ECUs for aviation application starting in 2017- 3 years before Brand X even had a viable ECU which wasn't glitching out all the time as the owner of Lancair told us in a phone call. (He contacted us because he was fed up having so many problems with Brand X.)

SDS has several options for coil mounting, both on and off the engine to suit client's need better. We did see some cracking in some Gen 1 four cylinder coil mounts. Issued a SB and replaced those at no charge with redesigned mounts. SDS uses the OEM coil connectors, not tacked on pigtails like Brand X. 6 cylinder systems logically use two 6 cylinder coil packs, not three 4 cylinder ones.

Our fuel system layout has no problems with hot starting, being proven in 118F OATs 15 minutes after a hot shutdown. More BS made up by Brand X. Our injectors mount where the factory Lycoming ones do- in cool air while in flight. Brand X mounts them in the primer ports on the bottom, subjected to high radiant heat from the adjacent exhaust pipes and bathed in hot cooling air coming down through the fins off the heads. They interfere with the oil drain back fittings and cowlings on some configurations. Their Mickey Mouse mounting (held together with crimp clamps!) with poorly designed and poorly machined captures, crack and have resulted in a fuel fire from failure. (no Service Bulletins ever put out by brand X after these failures!)We've had multiple Brand X customers come to us, wanting to buy our injector mounts. Our Top mount injectors and plumbing have no impact on cooling as everything is in the cool plenum area where there is huge volume compared to the inlet area. Another made up BS claim... Unlike Brand X, we've had zero O-ring failures because we run these areas MUCH cooler than Brand X- proven through actual thermocouple measurement. Lycoming also mounts their injectors on top.Brand X supplies an Aeromotive single diaphragm fuel pressure regulator which has had multiple ball and seat failures (see photos above). (no SB again by Brand X). The twin diaphragm Borla regulator has had zero failures. Borla has been selling EFI parts for over a decade but Brand X tries to tar them as a "muffler manufacturer". We don't include a "reprime orifice" because we don't need one with our fuel system layout. Zero issues in over 1 million flight hours.

SDS includes serviceable SDS made billet fuel filters. Brand X supplies cheap, disposable ones which have been known to leak.

SDS trigger magnets are easily mounted by the customer using our CNC'd drilling jig. You don't need to ship your flywheel like Brand X requires. We also offer lightweight billet flywheels with magnets already installed if you prefer. Timing doesn't need to be verified with a timing light- since 2019. Maybe you should with Brand X though, as they had the Magnet Position set wrong on their "Legacy" ECUs resulting in overly advanced timing for customers. Multiple customers came to us for advice on how to fix their high CHT problems. On Conti engines, we like the solid mounting the prop bolts offer for our trigger magnets. We don't like the poorly designed tack-on parts that Brand X uses here.

SDS doesn't offer an extra cost, single point of failure "Bus Manager". Never needed such a thing in over 1 million flight hours. We prefer the time proven, traditional, breaker at the power wire for each circuit.

A few more things Brand X left out of this document was that they supply, automotive, cast throttle bodies with a scabby, heavy adapter and that the throttle linkages crack on (see photo above and again, no SB here). Are you seeing a trend in denying failures by Brand X?). In fact, all their machined parts look scabby and are mostly not anodized as covered above.

Once you include their Bus Manager, Brand X system prices are $700-$1000 more than SDS.

Service Bulletins

We actually value the safety of our customers by putting out Service Bulletins when we see a problem with our parts. We are not perfect and we step up and provide new parts to address those issues. Brand X doesn't publish SBs on their website, prefering to pretend they are perfect and nothing ever breaks, even though we and they both know they've had multiple issues. That's dangerous in our view in the aviation world.

We are not the only ones who think the Brand X lack of response to design problems is dangerous. From one highly respected and experienced engineer in the Canard Community: (Paraphrased)-This is a generic warning regarding (Brand X) systems with regard to the FI portion of the equipment. Anyone with (Brand X) equipment on their aircraft should be exceedingly vigilant about failures and inspections.

In good conscience, not only can I not recommend purchase and usage of (Brand X), but I strongly discourage their purchase and usage. The company has not been responsive to failure reports and constructive feedback from me or a customer with extensive Air Force and canard flight test experience; has not accepted responsibility for known failures due to design, manufacturing or quality control; nor have they (to date) issued any Service Bulletins for known failures that have occurred.

More Disinformation

Brand X states on their website: "At 2750 rpm, the System32 ignition delivers more than 36 crankshaft degrees of continuous hot spark to ensure that the fuel gets lit. This means you can push the mixture deeper into the rich range for more power or further into the lean range for more efficiency." Nonsense. Best power as made at around 12.5 AFR. Going richer than that will LOSE power. Best economy is obtained at around 15 to 16 AFR. Going leaner than that will result in LOWER efficiency. Even this general information is erroneous, trying to paint an advantageous marketing picture.

Why Post This?

Fighting Fire (and Bullshit) With Facts.

We ignored Brand X after the split and just devoted our energies to designing new products and serving our customers but since they and their followers recently ramped up attacks on YouTube against SDS, we will no longer be silent while they continually trash talk our products and reputation with disinformation and lies in magazines, online and at aviation events such as Reno and Oshkosh. This went back to 2016, even while they were still buying our ECUs and programmers. When confronted with this information at that time, the head of Brand X naturally denied being associated with this development. Our suspicions were that this trash talk was coming directly from him and this was later confirmed in 2017. We take a very dim view when someone tries to destroy our business and livelihoods with lies and deceit like this. Had we wanted to take them out of the market, we could have terminated our supply of products to them back in early 2016 when the first signs of major friction and this trash talk emerged. Not wanting to destroy their business and income, we gave them the benefit of the doubt until Aug. 2017 when we confirmed that this trash talk was coming directly from Brand X and cut them off from further ECU shipments.

Now divorced from SDS, Brand X and their followers continued to spout nonsense and lies on forums and magazines about SDS and ban other members on aviation Facebook pages who dare question them for facts about their ridiculous assertions towards SDS. They had told their customers that we were nearly bankrupt and would be out of business in 2017 (not very nice). Too bad for them- 2022 was our best year in 15 years and SDS continues to develop new products for this market, embraced by a growing number of builders and racers who see through their bullshit and demand the best- Andy Findlay, Dave Anders, Kyle Fowler, Marvin McGraw and hundreds of others all use SDS.

At Reno 2018, many pilots came by and told us that Mr. Brand X himself was completely trash talking SDS at his booth there- more so than even talking about their own new products! All this, while the Brand X customer flagship plane at the event failed to even qualify after multiple technical issues. At the same event, SDS crushed the Brand X hype with it's superiority by actually winning Sport Gold in Andy Findlay's Lancair. No trash talk, no bullshit, just real-world results.

Instead of simply building and promoting their own new products to compete with SDS, they chose to take this attack vector against SDS and we're finally fed up with it. This page is a response to these attacks. Their latest tactic, producing some "hit piece" videos on YouTube trashing SDS yet again, have been answered in kind, both on this page and YT video (see link at bottom of page). Watch this space for more facts and video links. Ye reap what ye sow. We didn't start this mess but we won't take this sort of crap without response any more.

To our competitor and his vocal sidekicks- you've failed to discredit us and destroy our business. Your hate, poisonous comments, deceit and mendacity has only undermined your own reputation and business and sent more customers over to SDS. Thanks. That's Karma, enjoy it...

"History shows that people engaging in the big lie always avoid debate" A great quote from Tony Heller. Every time the competitor has been asked on forums or groups to support their crazy, anti-SDS statements with facts, they are silent or go ballistic and flip out. The Brand X competitor and his sidekicks multiple meltdowns on various forums and groups over the years were epic. You showed your true colors. Nuf said... We saw this again in Feb. 2021 on VAF where Brand X won't respond to simple technical questions because he knows he'll be shut down by factual arguments in response to his false, BS marketing posts. The Brand X owner was finally banned from VAF for his crazy outbursts.

We suggest you don't take our word for things nor what the competition says. Do your own independent research before you put down your hard earned money.

I want to thank all our customers and other fine people who have have defended SDS against these lies, even if they face abuse or removal from the online forums and groups. We really appreciate this support!

YouTube vid countering this disinformation