Sales phone number 403-671-4015

E-mail:racetech1@telus.net

Last update April 2125

***Please note that SDS Aero products are only for use on Experimental/ amateur built aircraft. Not for use on certified aircraft.***

SDS CPI (Coil Pack Ignition)(Aviation Applications)

Programmable aircraft electronic ignition system. See new CPI-2 here: CPI-2 See automotive CPI info here: CPI

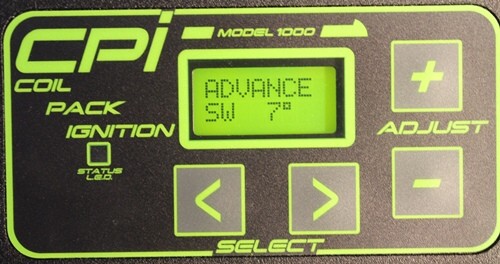

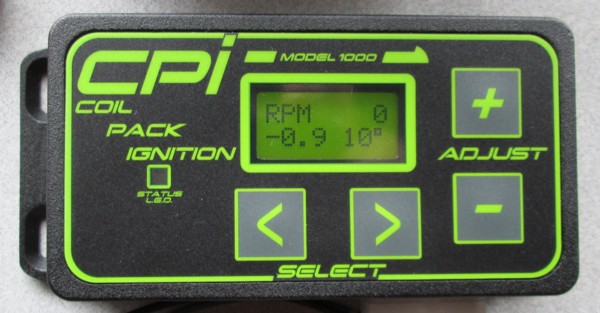

Keypad/ module

Lightweight, simple, feature packed, easy to use, programmable aircraft electronic ignition

The CPI is a programmable, stand alone, crank triggered, distributorless ignition system for 4, 6 and 8 cylinder engines. The primary target market is aviation engines equipped with carburetors or mechanical fuel injection. Comes complete with coil pack, crank sensor, magnets, wiring harness, vacuum hose, manual. Compared to older aircraft electronic ignitions, the CPI is smaller, lighter and has more features. The CPI is user programmable (in flight if you wish) via the integrated keypad. No PC required, no extra cost, 3rd party programmer, no scheduled maintenance to perform. Easy to advance timing when running Lean of Peak for maximum power and fuel economy.

Kit prices start at $875US for some basic 4 cylinder engines like Jabiru 2200 and Rotax 912(single coil pack, without plug wires). We'll tailor wiring harnesses and optional items to suit each customer's specific requirements. Best to email us here for your needs and a quote: racetech7@proton.me Please note that these prices are not for the automotive kits that we also offer here: CPI

Note that as of Feb. 3/25, systems for US customers will not include some items shown here due to recent tariffs. We'll include a list of vendors and part numbers to obtain these parts within the USA. Contact us for the latest pricing.

Please note, the CPI is not suitable for hand propped engines, you must have a starter

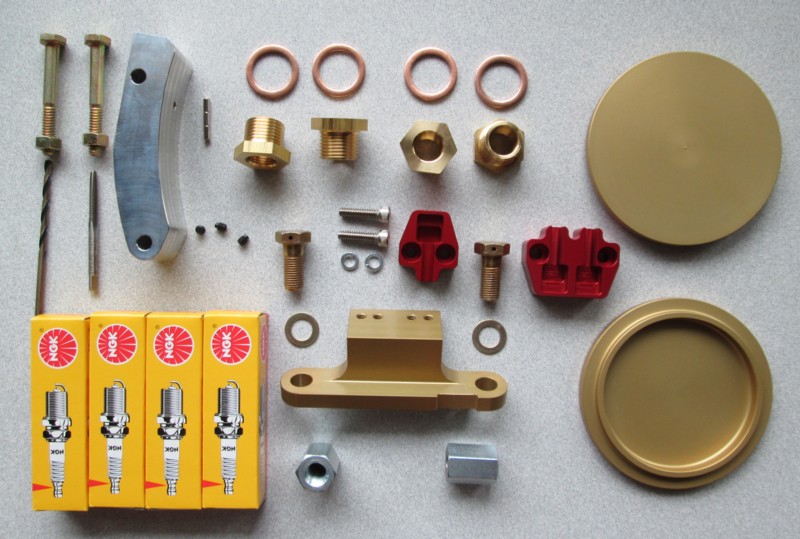

Complete Lycoming 540 kit. Note that as of Feb. 3/25, systems for US customers will not include some items shown here due to recent tariffs. We'll include a list of vendors and part numbers to obtain these parts within the USA. Contact us for the latest pricing.

Spark plugs and adapters for long reach Angle Valve Lycomings (IO-390/ 580)

Rotax 912 single CPI kit

CPI Features

Note the CPI should only be used with resistor type spark plugs and good quality, EMI/ RFI suppression type plug wires. Never use non-resistor plugs or solid core wires. We can supply quality MSD plug wire, boots and terminals for most engines.

The Lean of Peak Switch Advantage

While other aviation EIs give you a canned timing curve which is often secret and hard to adjust, usually requiring extra cost options to observe and change, SDS CPI makes basic timing adjustments quick and easy to do and our LOP switch optimizes ignition advance when running LOP. This feature extracts all possible energy from the fuel, picking up a few knots which are lost when running leaner mixtures.

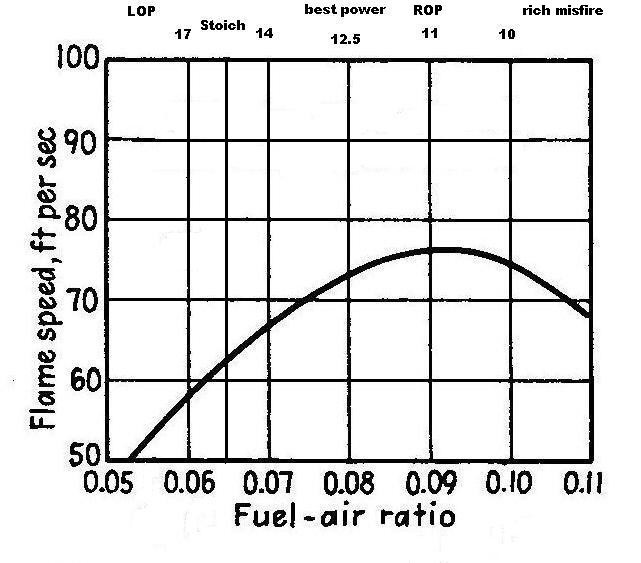

The figure below illustrates how combustion flame speed changes with air/ fuel ratio.

Notice how much flame speed slows down with lean mixture here. The SDS LOP switch advances timing when you are running LOP to achieve peak cylinder pressure at the optimal point for best torque.

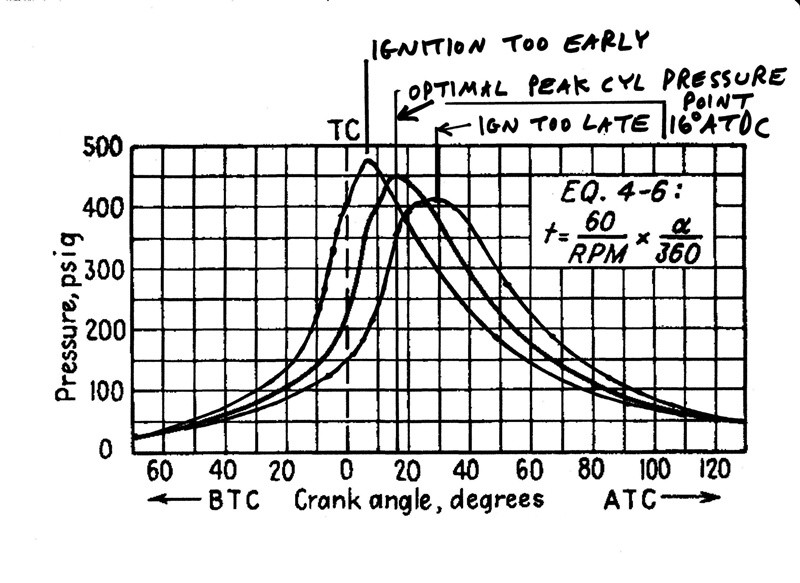

Notice how advanced or retarded timing affects the pressure vs. crankpin position curve. Unlike magnetos with fixed timing, CPI can deliver optimal ignition timing under all mixture, rpm and load conditions. EIs which cannot adjust timing when running LOP, lose efficiency compared with CPI

A couple videos showing basic features and programming and CPI hardware:

https://www.youtube.com/watch?v=lBEOQdZBOS8

hhttps://www.youtube.com/watch?v=olQwqfxm2BE

Video of Magnet Position set up on a Lycoming engine: https://www.youtube.com/watch?v=6-7K-GA35f4&feature=youtu.be

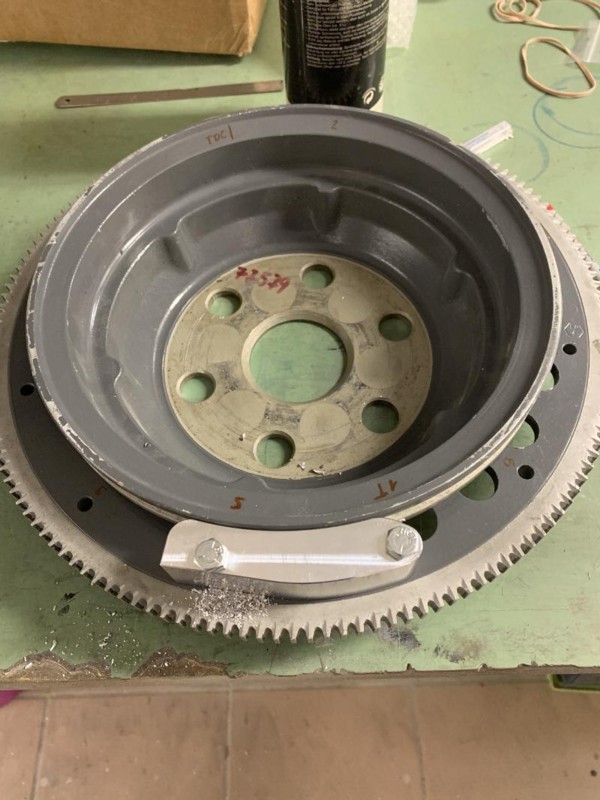

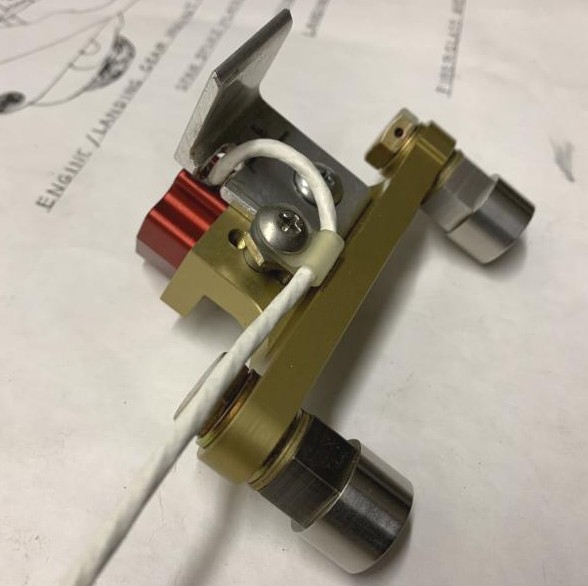

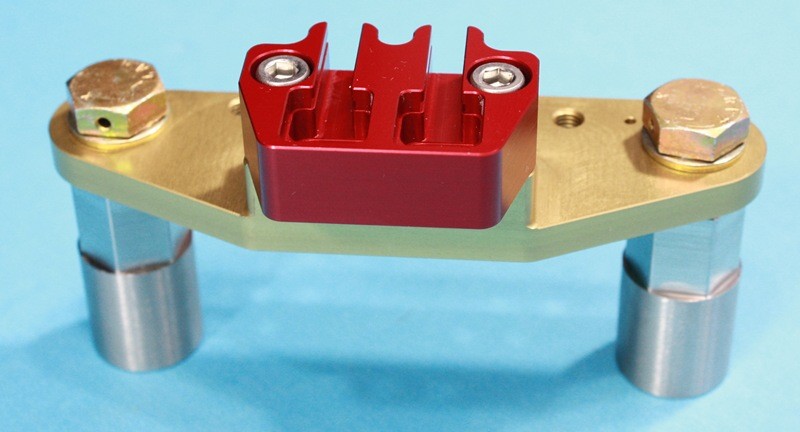

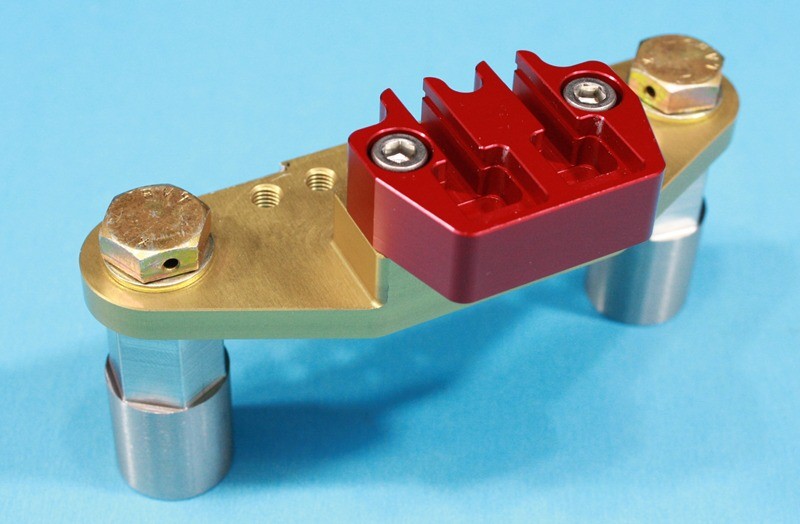

Lycoming 320/360 ignition kit includes Magneto cover, single or dual Hall sensor and mount, hardware, automotive plug adapters and plugs plus drilling block, drill and tap to mount magnets into OE flywheel, optional panel mount kit, MSD 8.5mm wire sets and wiring harness also included (not shown). Fits engines with 8 7/16 ID flywheel only. Prices range from $1120 to $1170US for a single setup firing one set of plugs, $1965 to $2185 for dual setup firing both sets of plugs, depending on options. On engines with long reach plugs (identified with yellow center head finning), add $68 per system for longer plug adapters and Denso Iridium plugs. Wiring harnesses can be custom tailored to your needs and any items not desired can be deleted from the kit. Note, you must drill and tap your own flywheel for the triggering magnets with the drilling kit provided.

Please note: our magnet mounting system for Lycoming engines is not compatible with the Sky Dynamics lightweight flywheels, new Lycoming flywheels lacking the 12 tooling holes around the periphery or factory dual pulley groove flywheels. We do have a solution for Airflow Systems aftermarket flywheels for driving a/c compressors.

Photos showing some of the basic screens here:

Advance switch screen

Magnet alignment window

RPM timing advance window

Manifold pressure advance window

Manifold pressure retard window

Programming resolution is 1 degree. Timing values are shown in true degrees. Full control given to the user over the entire timing map from cranking retard to rpm (every 100 rpm) to MAP (every 1.2 inches) plus advance switch amounts. No clumsy, extra cost programming interfaces like Lightspeed, P-MAG offers.

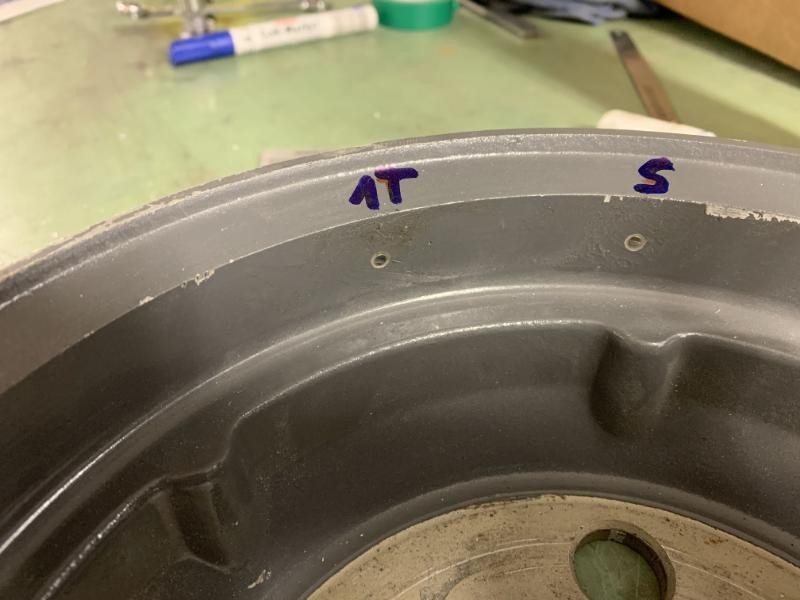

You must have the larger 9.75 inch OD Lycoming flywheel to mount our magnets and crank sensor.

ID near belt groove should measure 8 7/16 inches.

OD of belt groove should measure 9 3/4 inches.

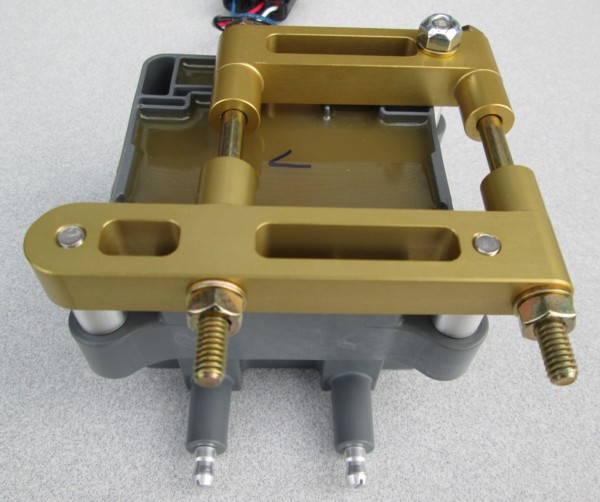

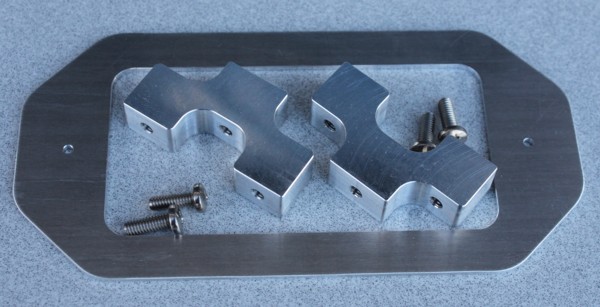

Coil mount kit for 4 cylinder Lycoming engines. Mounts to top rear of crankcase. Does not fit narrow deck engines. See photo below.

For reference, this is what a narrow deck Lycoming case looks like. Note deep recesses for top case bolts.

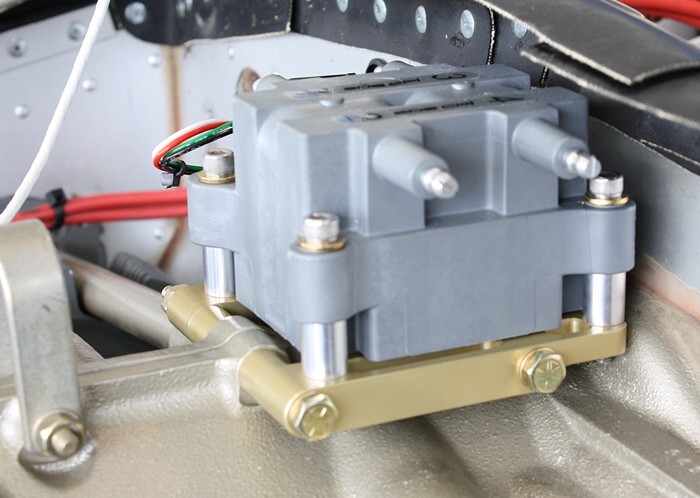

Top case coil mount on wide deck engine.

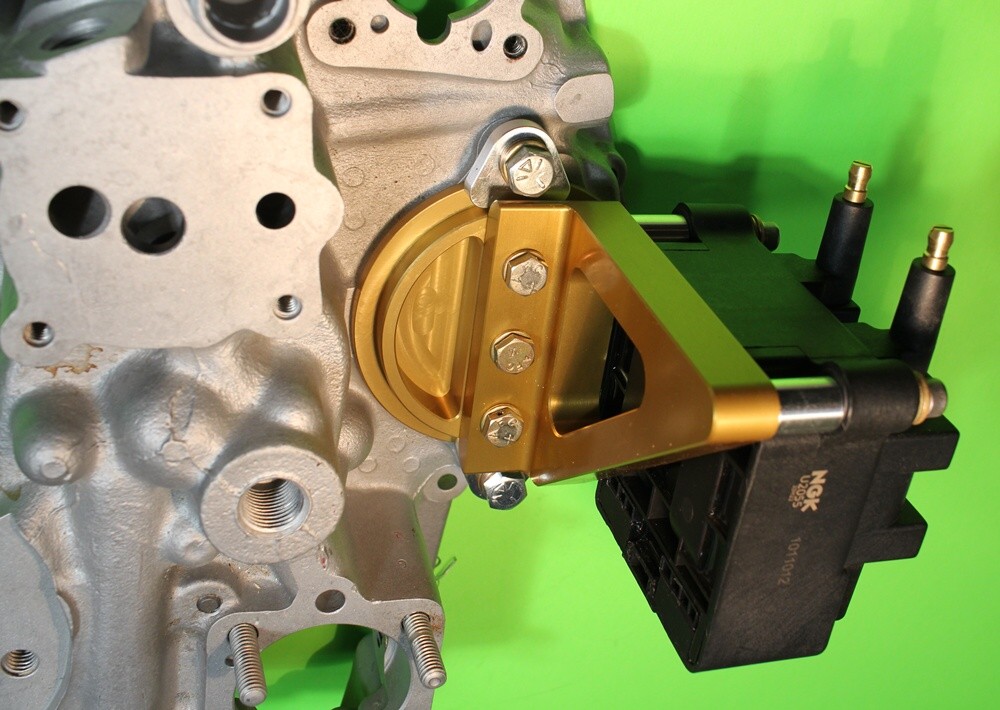

Rear mount for coil packs on 4 cylinder Lycoming engines. Mounts in place of magnetos.

540 top coil mount

***Please be sure to measure your front case bolt spacing on Lycoming engines before ordering. This dimension can be either 3.25 or 3.50 inches.***

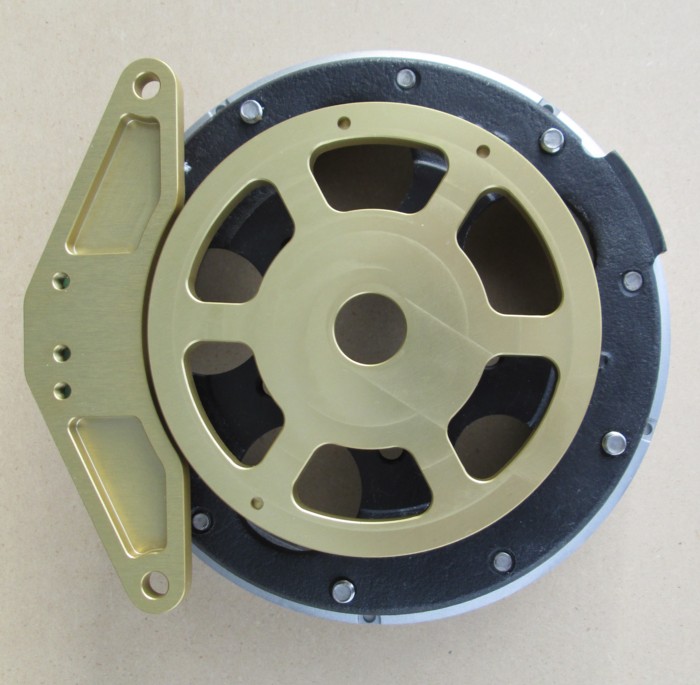

Replace your crude factory Rotax ignition with CPI. New lightweight Rotax 912/914 magnet disc and Hall sensor mount. Dynamo ring not included.

Jabiru 2200/3300 Magnet disc and Hall sensor mount

For aircraft system pricing, options and wiring harness lengths and termination preferences, please contact us:

E-mail: racetech7@proton.me

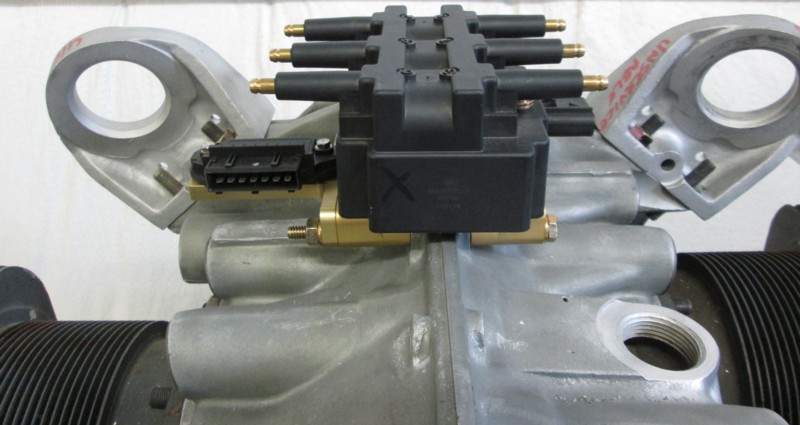

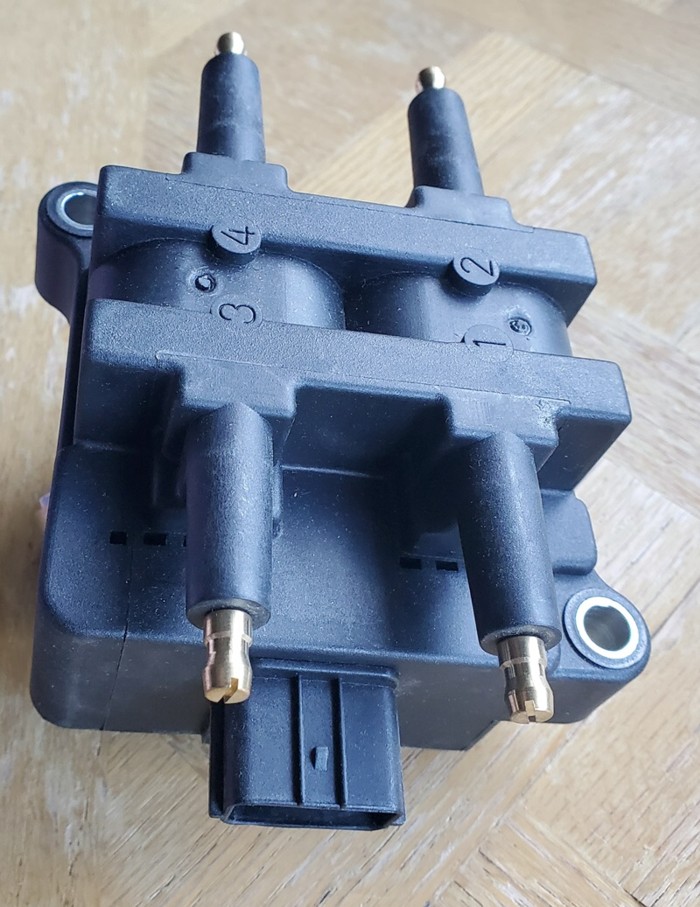

Subaru type coil pack supplied for 4 and 8 cylinder engines and twin plug, 4 cylinder engines

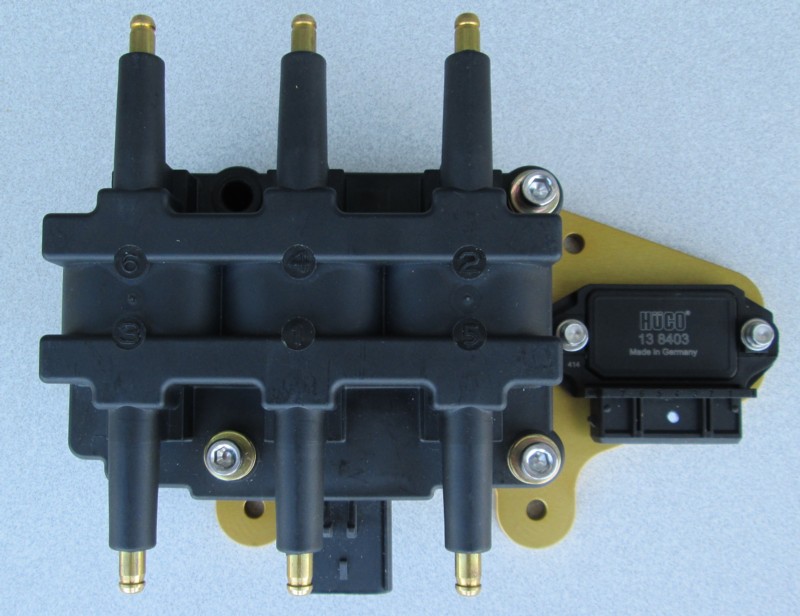

Coil pack supplied for 6 cylinder engines with module, mounting bracket and heat sink. 3.6 pounds

Coil mounting hardware kit included

LCD shown in gauge mode

Optional Panel Mount Kit

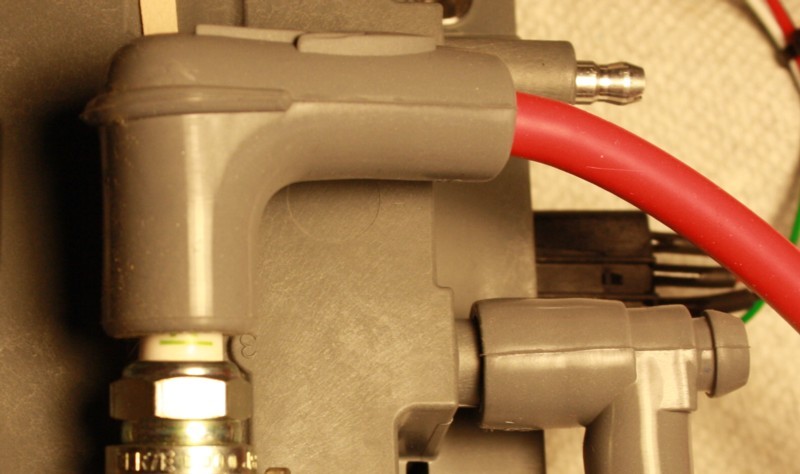

Panel mount blocks on CPI

Blocks, hardware and drilling/ scribing template

Block detail

Template over CPI face

Approximate System weights

Single 4 cylinder CPI driving one set of plugs- 4.5 pounds

Single 6 cylinder CPI driving one set of plugs- 5.5 pounds

Dual 4 cylinder CPI driving 2 sets of plugs- 8.5 pounds

Dual 6 cylinder CPI driving 2 sets of plugs- 10.5 pounds

Note that there are slight differences in coil mount weights

MSD Plug Wires and Boots

Be sure you push the plug and coil boots all the way down to engage the terminals fully. There should be about a 1/8 inch gap as shown in the photo below

MSD Plug Wire Part Numbers

The following bulk PNs fit all coil packs:

34049 8.5mm red Superconductor wire

34615 90 degree terminal (plug and coil)

34555 90 degree coil boot

34515 90 degree plug boot

Recommended MSD plug wire crimping tool PN 35051

Video for building your MSD plug wire set

Customer Install Photos

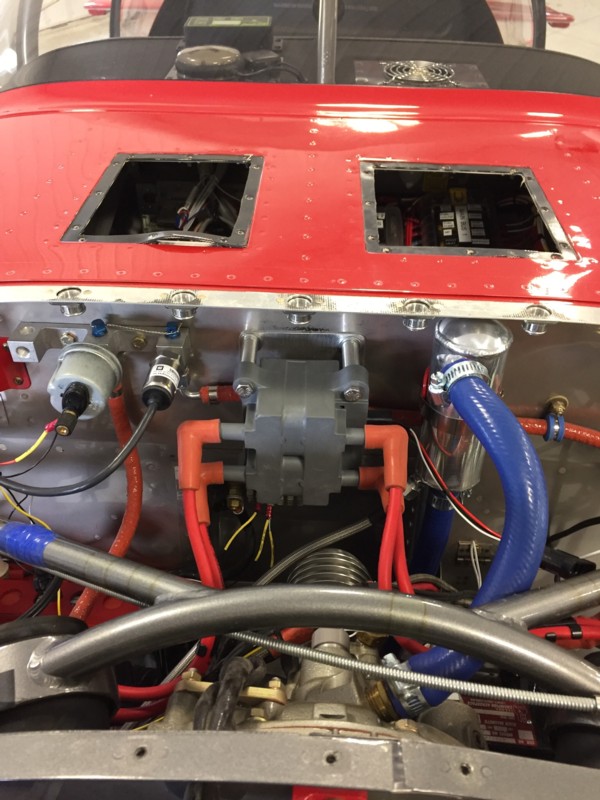

Carlos Lopez's immaculate Lancair Legacy in Argentina, dual CPI equipped

See multiple installation and aircraft photos here

Tim Wall's amazing 70% Spitfire scale replica. Buick 3.5L V8 powered.

Hall sensor installation

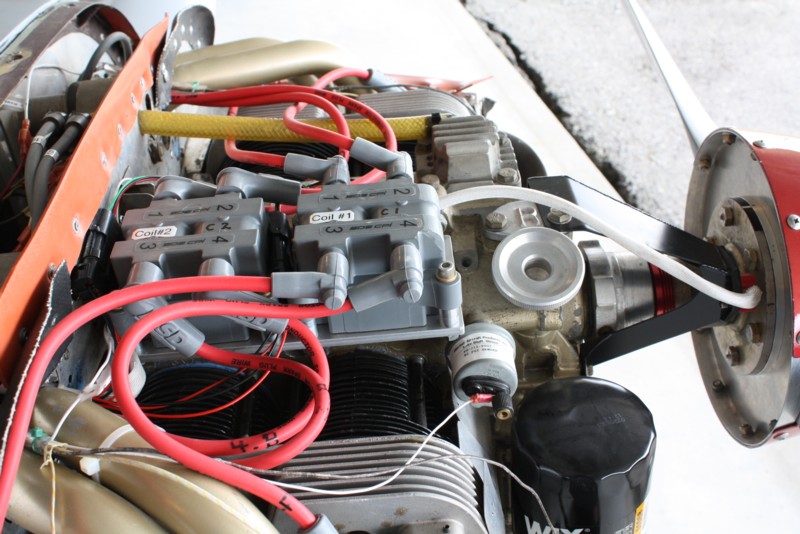

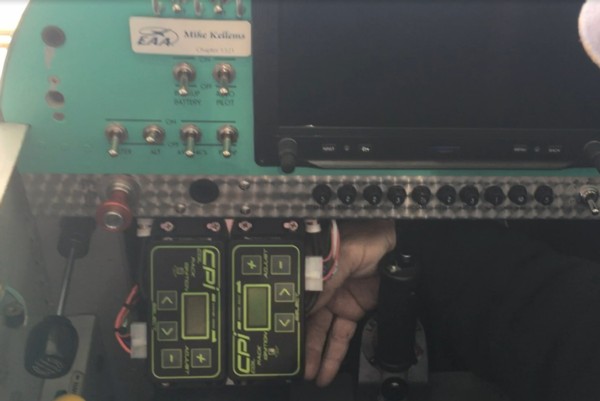

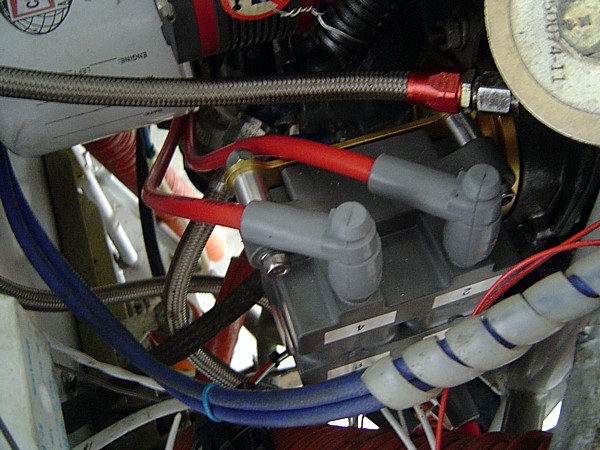

CPI controller

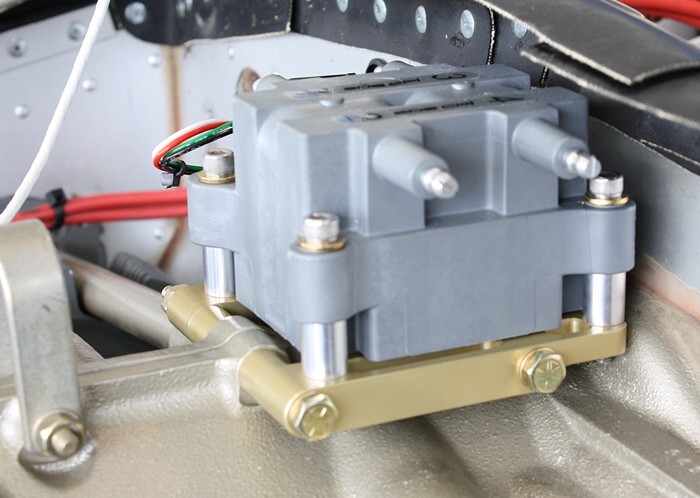

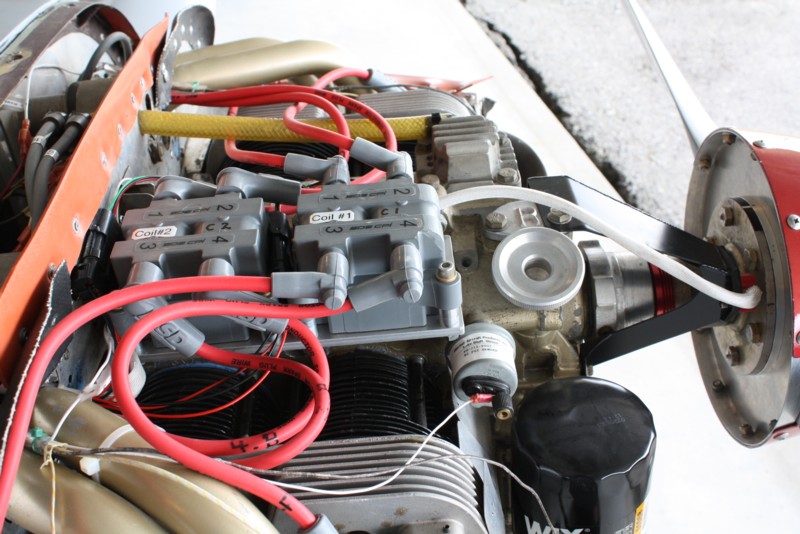

Coil pack installation

LS powered Few Mustang

Install on VW engine

Photos of nice install on O-360 Lycoming from Karsten Lorenz

CPI flush mounted to panel

Dual CPI install on Mike Kellems' RV-3B

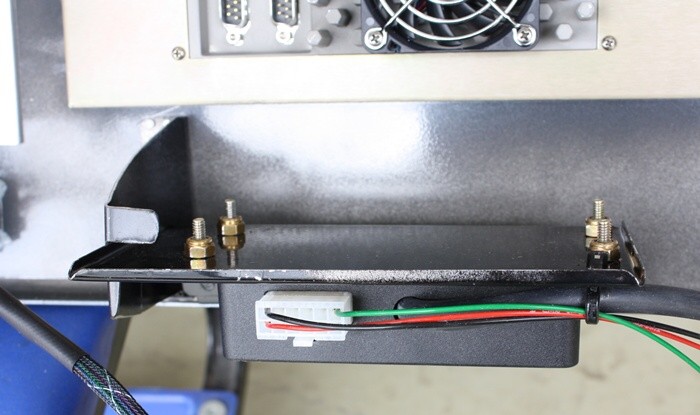

Dual CPIs mounted on fold down, hinged panel

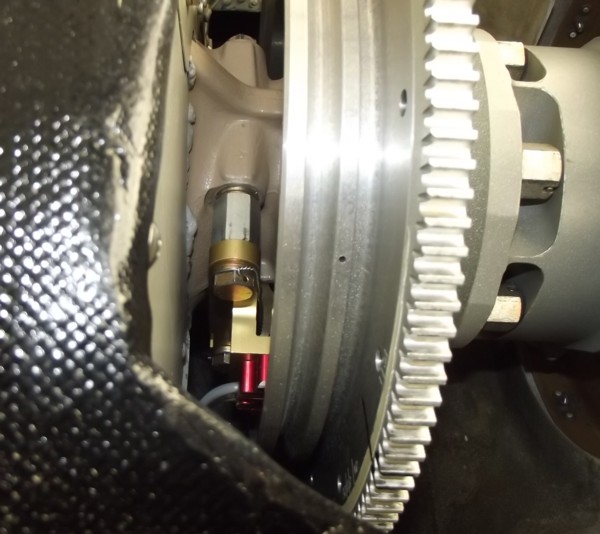

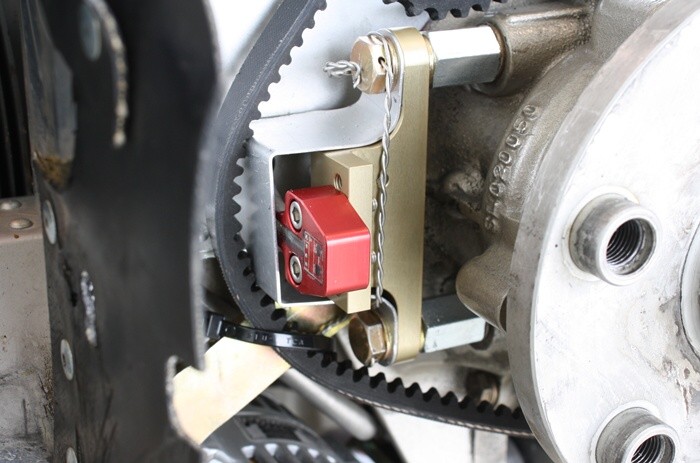

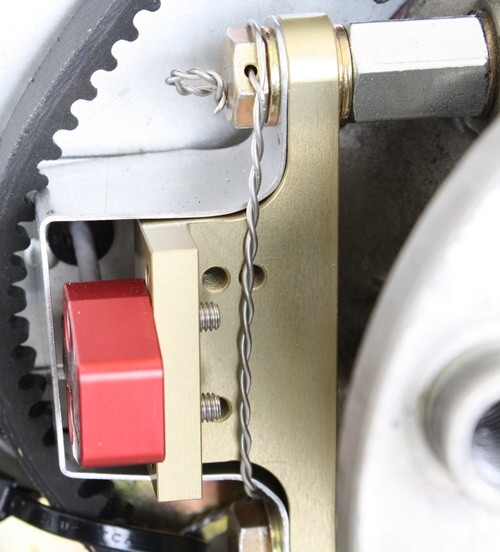

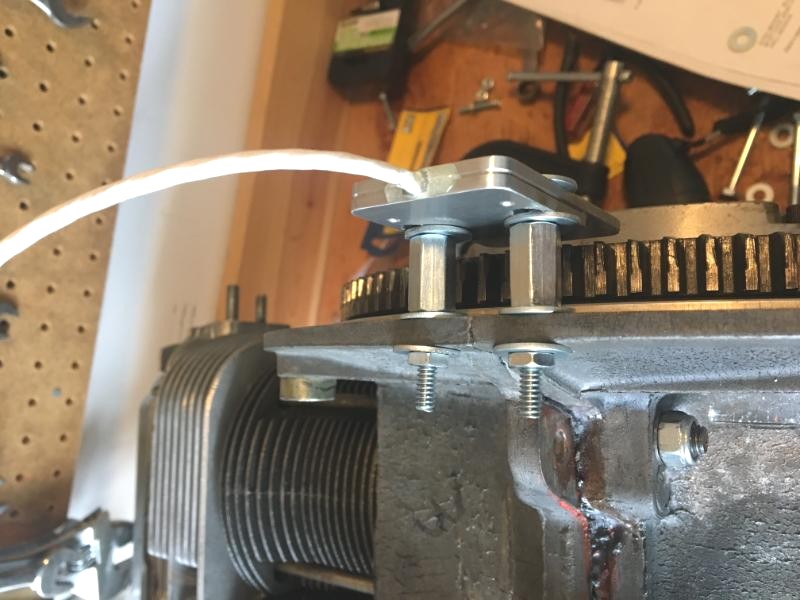

SDS billet flywheel and coil mounting detail

Hall sensor mounting detail

Marv Wessel's award winning Lancair ES fitted with dual CPIs

CPIs mounted behind panel

CPI coil pack installation on Ivan Kristensen's RV10

Hall sensor cable armoring detail

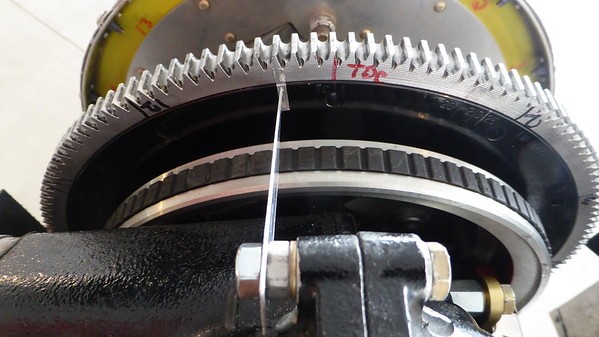

Temporary pointer installed to set Magnet Position

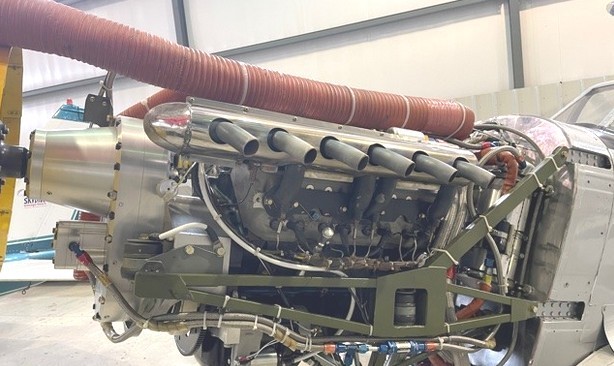

CPI-6 coil pack, crank sensor installation on Mike Robinson's Lycoming IO-540 powered Rocket

Adam Pontious' very nice Rocket with CPI

Photos of Hall mount for 3.50 inch case bolt spacing

Dual CPI panel installation in Steve Alderman's Lancair

Steve Alderman's Lancair

Lycoming 540 rear coil pack mount

Rear coil mount on Lycoming O-320

Simon Jarman's lovely O-320 powered Glastar in France with CPI-4. Nov. 2016 update from Simon- "...I have been running your CPI unit for 8 months, and so far it is a fix and forget solution. The engine always starts hot or cold and there is no rpm drop on turning off my magneto, so the CPI seems to be doing all the work. I am saving some fuel too. On a recent trip to Spain at 8000' I averaged 19.6 mpg out and 21.4 mpg back, difference due to wind. Previously I was seeing about 18 mpg"

Crank trigger detail on Lycoming 360/ Lancair

Firewall mount of CPI coil pack on Neil McLaren's RV6, Aerosport 375 engine

Here are some installation photos on a 360 Lycoming done by Ralph Inkster on an RV.

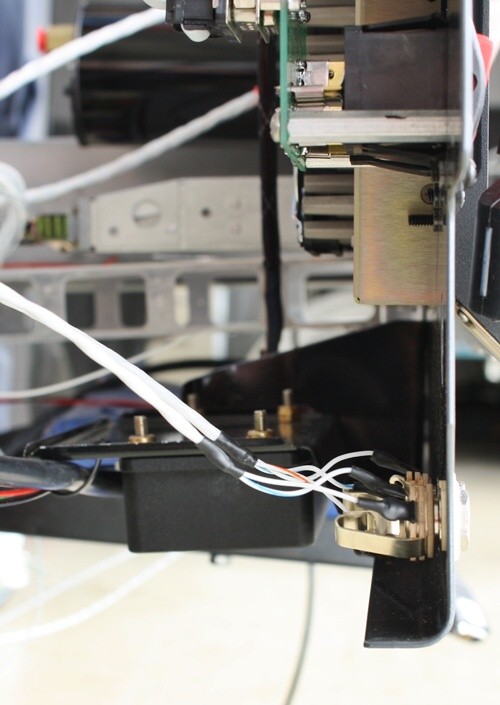

Crank sensor mount and cable shield detail

Sensor cable penetration of baffling

Top coil pack mount. This saves penetrating baffling with spark plug wires

Crank sensor cable routing

Hinged CPI mount under panel in retracted position

In extended position

End view retracted position

Some photos of Sam Spanovich's Revmaster 2100 powered KR2S with SDS CPI

Crank sensor mounting detail

Some photos of Calvin Thorne's CPI installation on his VW powered Quickie

CPI Documentation

For main aero CPI installation and tuning manual click here Revised April 4/22

For CPI aircraft supplement guide click here Revised Mar. 20/22

Lycoming 4 cylinder magnet mounting Revised Oct. 23/19

Lycoming 6 cylinder magnet mounting Revised Oct. 23/19

Basic wiring and switch layout for dual 6 cylinder CPI

Video on CPI internal Spark Test Function

Service Bulletins

Sept. 2/19 Setting Magnet Position

We've eliminated the need to set Magnet Position with a timing light on Lycoming engines. For engine using the dual pickup, set Primary ECU Magnet Position to 97 and Backup to 88. For single pickup installations, set it to 92.

April 26/19 Service Bulletin Regarding 18 to 14mm Spark Plug Adapter Installation

Due to a number of broken brass plug adapters, we've changed the procedure for installing these as follows: 1. Thread the spark plug into the adapter 2. Torque the assembly into the cylinder head using the PLUG hex to 19 ft./lbs. 3. Torque the ADAPTER further to 25 ft./lbs. Use only a thin stripe of anti-seize compound on the plug and adapter. Do not coat the threads. Although we've done multiple yield tests on the adapters torqued into a fixture and they fail at 32-35 ft./lbs., a number of people were snapping them at the originally recommended torque of 22 ft./lbs.

Magneto Parts to Remove on 6 Cylinder Lycoming Engines

Exploded view of magneto parts on Lycoming 540 engines: 540magparts.pdf

When replacing the mags on 6 cylinder Lycoming engines, be sure to remove the gear/ cup (6), cush drive (2) and pilot bearing (7) as shown above. Be very careful not to drop any of the parts into the sump! The extension housing (4) may be removed or left in place as desired

For other aviation product information, click here: Aircraft