Last updated June 27/23

Please note, the information here primarily applies to SDS automotive systems. For aviation specific information please click. Aircraft

The SDS EM-6 can replace the entire factory EFI system on most engines or upgrade older carbureted engines to port type fuel injection with ignition control.

SDS eliminates MAF sensors and old style AFMs.

By selecting the correct MAP sensor, boost pressures up to 60 psi may be used. EM-6 is designed to control port type injection only. It can be configured to drive low or high impedance injectors and gives a good idle even with very large injectors fitted.

New EM-6 offers targeted closed loop capability plus can optionally log to a card instead of using a laptop.

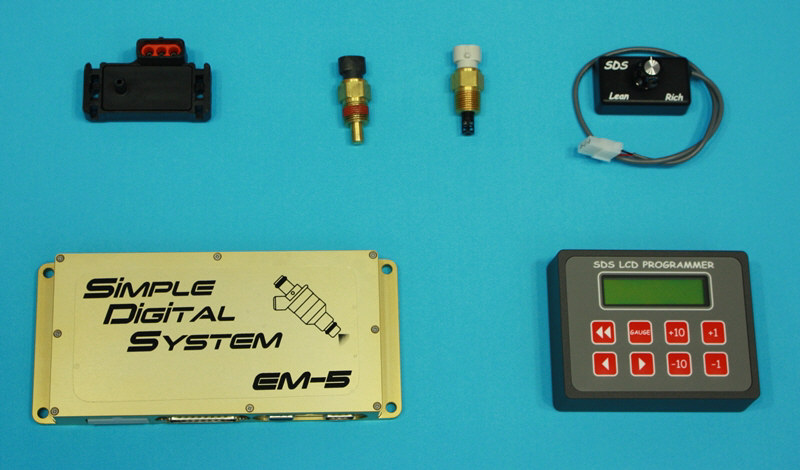

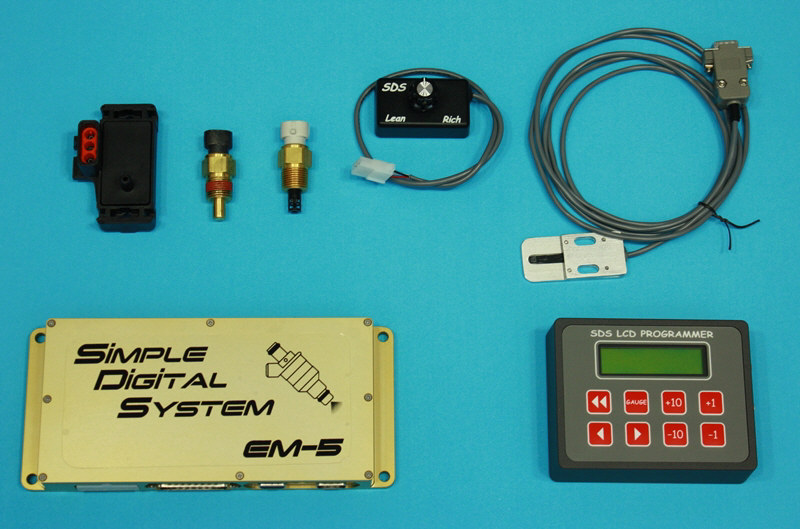

Systems Include:

- ECU

- Backlit LCD programmer

- Air temp sensor

- Water temp sensor

- Main wiring harness

- Injector harness\

- Fuel trim control, +, - 50%

- Comprehensive manual

- Crank sensor (E,F)

- Timing magnets (E,F)

- Coil/amp unit (F)

- Check engine lamp

Adjustable Parameters

- RPM - every 250 (100 rpm for direct drive aviation engines)

- Manifold pressure - 64 locations

- Water temperature - 32 locations

- Start function - 33 adjustments

- Acceleration - 3 adjustments

- Closed loop - 5 adjustments

- Boost limiting

- Rev limiting

- Ignition timing - every 250 (E,F)

- MAP retard - 64 locations (E,F)

- Knock control (optional on E,F)

- RPM switch - every 250 (optional)

- Nitrous ignition retard (E, F)

- Fast idle temp cutoff - 32 locations (optional)

- Data logging AFRs vs. RPM

Extra Cost and Optional Items

- MAP sensors (1,2 and 3 Bar)

- CHT sensor

- Knock sensors

- Oxygen sensors (1 and 3 wire)

- Fuel pump relays

- Fast idle solenoids

- Injectors

- Fuel pumps

- RPM switch

- TPS

- Electric fan switch relays

- Supercharger switch relays

- Air conditioning solenoids

- 8 channel data logging to PC or to data card (EM-6 only)

- 15,000 rpm software

ECU to PC data logging

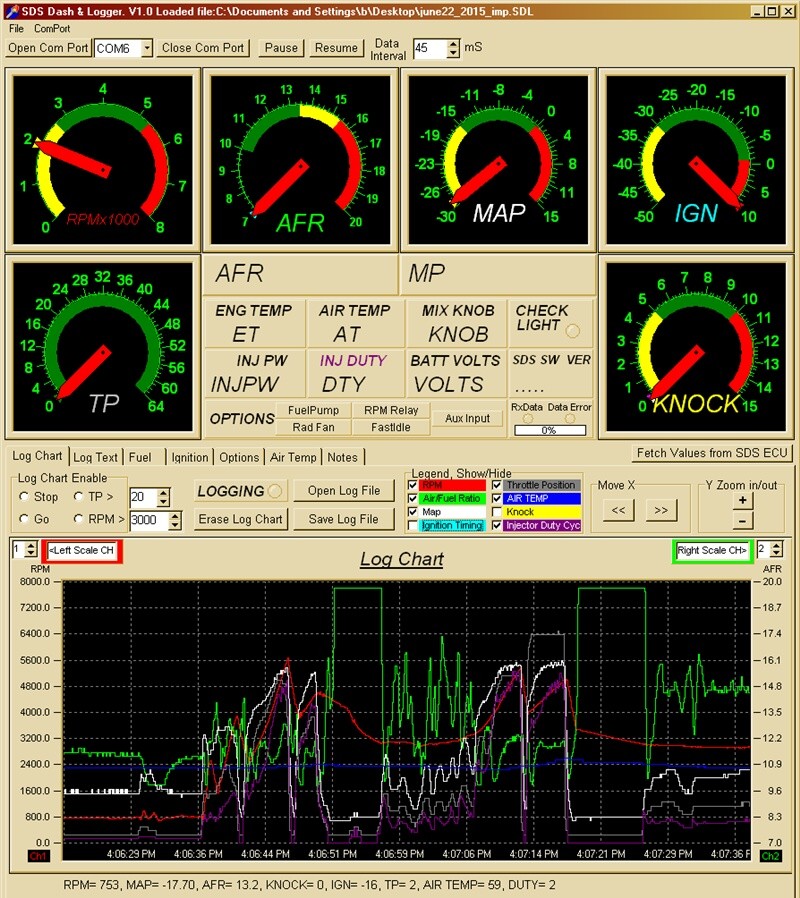

Optional 8 channel, gauge package and data logging to PC feature allows the user to log and store MAP, RPM, ignition timing, IAT, AFR, throttle angle, knock activity and injector duty cycle in text format (EM-5/6 ECUs only). Gauge package displays engine temp, injector pulse width, mixture knob position, and battery voltage in real time. Feature also allows you to save and print the values from the ECU. Windows XP, 7, 8.1, 10 compatible. This plug-in kit is only available for EM-5/6 ECUs with the round data port hole in the ECU. $110US. We send the PC software by email. Please note, there is no onboard memory, you log directly into a laptop. EM-6 only can log to a memory card with optional card logger module.

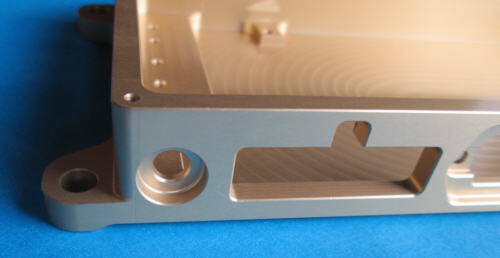

You need to have this round port on the left of the ECU box to install the PC data logging kit. Systems purchased after August 13/14 should have compatible V25 software as well as the data port hole. Older version EM-5s can be reflashed to V31 if you have the data port hole (starting on some models May 28/14). We can drill older EM-5 ECUs for the data port for an extra $25. EM-3 and EM-4 ECUs can have this capability added by swapping in an EM-6 board for $610US.

Injector Compatibility

SDS will drive most low impedance (1.7 to 3 ohm) or high impedance (12 to 16 ohm) injectors. The injector impedance must be known when ordering so that we may supply the correct injector drive harness for those injectors. The system is intended to work with port type injection only (one injector per cylinder).

Weights and Dimensions

D systems weigh approx 6 lbs.

E systems weigh approx 6 lbs.

4F systems weigh approx 9 lbs.

6F systems weigh approx 11 lbs.

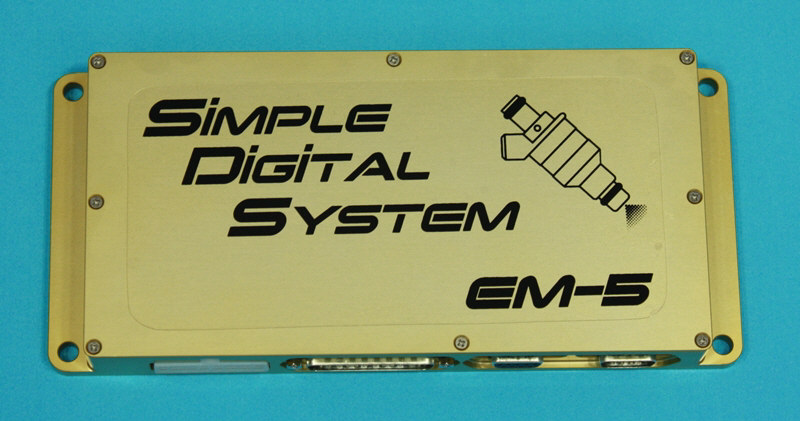

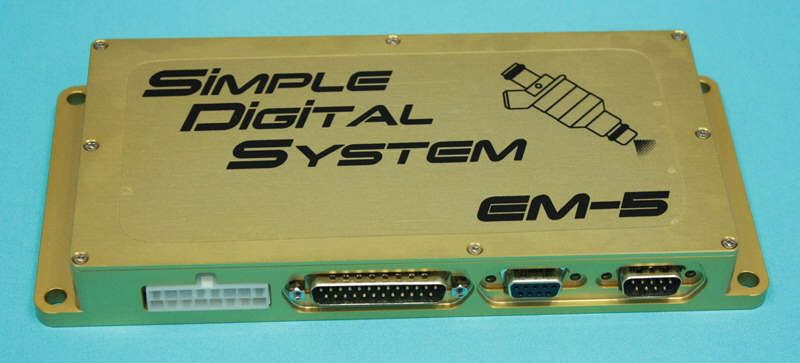

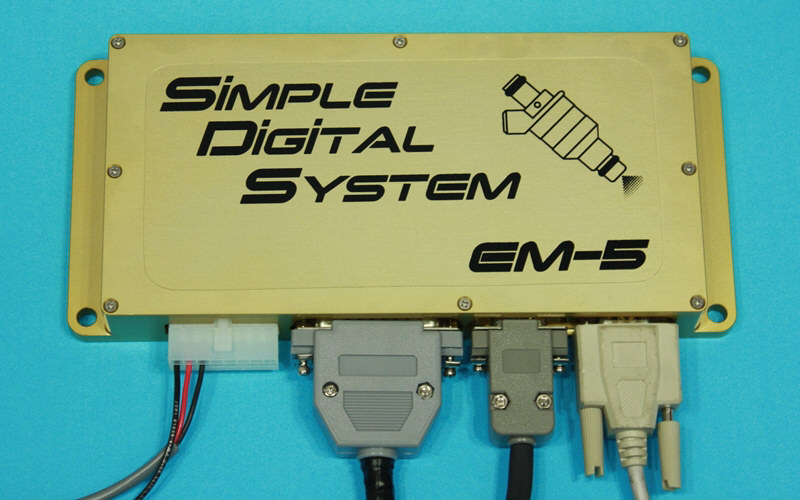

ECU dimensions are 3.875 x 8.5 x 1 inches, gold anodized, 6061T6, CNC'd billet.

If your engine is not equipped with EFI hardware such as injectors and a high pressure pump, you will need the following items in addition to one of our systems to convert to EFI:

Fuel injectors

Fuel pressure regulator

Fuel rail

Fuel pump

Fuel return line from regulator to fuel tank

Throttle body

If no suitable EFI manifold is made for your engine, you will have to weld injector bosses to your present manifold, make a fuel rail and mount a throttle position sensor. Details on some of these aspects are available on our Tech Page at: Tech Page/FAQ. Cars equipped with CIS (K Jetronic) mechanical injection, also need extensive modification to convert to EFI, including new injectors.

Temperature Sensors

All EM-6 systems include an air temperature sensor for measuring inlet charge temperature and either a water temp sensor for liquid cooled engines or a cylinder head temp sensor for air cooled engines. Normally, systems are shipped with 3/8 NPT GM temp sensors for liquid cooled engines with Weatherpack connectors. Air cooled engines are supplied with a GM air temp and a 1/8 NPT CHT sensor. Optional choices for liquid cooled engines are smaller 1/8 NPT sensors without waterproof connectors or Bosch 12 X 1.5 mm sensors with waterproof connectors. If you don't specify, you will receive GM sensors. Temperature calibrations may be in either Celcius or Fahrenheit, which should be specified at the time of ordering. For photos of the different sensors available: tempsens.htm

EM-6D Digital fuel injection control

The D system offers complete control of port type injectors on 3, 4, 5, 6 and 8 cylinder engines. RPM ranges of 9750 or 15,000 are available. Fuel values are all fully programmable. Boost pressures of up to 30 psi can be accomodated. MAP sensor shown is not included in standard pricing.

Installation of the D system is simple and quick, just 2 grounds, 2 powers and the tach wire hookup. All other sensor connections are straight plug-ins with the supplied wiring harness and pre-installed connectors. A crank trigger sensor is often required to supply a clean tach signal to the ECU.

Base system prices USD: 4D- $1125, 6D- $1170, 8D- $1242

EM-6E/MSD Digital fuel injection and ignition control for 4, 6 and 8 cylinder engines equipped with distributors

The E/MSD system offers control of both fuel injection and ignition timing in a single, integrated package. Ignition is crank triggered with capability to 9750 rpm. It is programmable for fuel and ignition values and have ignition retard capability under boost and with nitrous activation. OEM style ignition wires can be used. MAP sensor shown is not included in standard pricing.

The system is configured to trigger an MSD-6A directly from the ECU. MSD 2 step rev limiters are compatible with this system. No coil is included with the MSD configured units. The E system requires fabrication of a bracket to mount the crank sensor and installation of trigger magnets into the crank pulley.

Base system prices USD: 4E/MSD- $1348, 6E/MSD- $1414, 8E/MSD- $1521

EM5-/4F/6F/8F Digital fuel injection control and direct fire ignition for even fire 4, 6 and 8 cylinder engines

The 4F system, shown above, controls fuel delivery and ignition timing on 4 cylinder engines to 9750 rpm (15,000 optional). Its crank triggered, direct fire coil pack replaces both distributor type and OEM distributorless ignitions. It is programmable in 250 rpm increments with 64 boost retard locations available for turbocharged engines and ignition retard under nitrous activation. MAP sensor shown is not included in standard pricing.

The standard F delivers a powerful, long duration spark and is suitable on engines with specific power outputs of up to 200hp/liter. The 4F comes complete with coils and crank trigger. Fabrication of a crank sensor mount and installation of trigger magnets is required.

Base system prices USD: 4F as shown above- $1654, 4F for MSD DIS-2 no coils or driver $1464, 4F to drive OE waste spark coil pack $1579

The 6F system, shown above, controls fuel delivery and ignition timing on even fire, 6 cylinder engines to 9750 rpm. Its crank triggered, direct fire coil pack replaces both distributor type and OEM distributorless ignitions. It is programmable in 250 rpm increments with 64 boost retard locations available for turbocharged engines and ignition retard under nitrous activation. MAP sensor shown is not included in standard pricing.

The standard F delivers a powerful, long duration spark and is suitable on engines with specific power outputs of up to 200hp/L. The 6F comes complete with coils and crank trigger. Fabrication of a crank sensor mount and installation of trigger magnets is required.

Base system price USD: EM-6 6F- $1785

Base system price USD: EM-6 8F- $2079 (Not pictured)

Prices do not include fuel injectors, pumps or optional items listed below.

For Ford EEC equipped vehicles, check out the SDS plug-in systems offered by Western Motorsports on our Dealer/Links Page or: www.wmsracing.com

Which System Do I Need?

| Engine Type/ Required Control | 4 Cyl. | 6 Cyl. | 8 Cyl. | |

|---|---|---|---|---|

| Don't need ECU controlled ignition | 4D | 6D | 8D | |

| Need ignition control, engine has distributor | 4E/MSD | 6E/MSD | 8E/MSD | |

| Need distributorless ignition control | 4F | 6F |

For a wide variety of engines and cars fitted with SDS units: Project Page

Connections and Wiring

The EM-6 ECU uses 4 connectors arranged on one side. The left plug is for injector drive wires and options. The DB25 connector is for sensor, ignition trigger wires and ECU power. The DB9, 2nd from the right, is for the Hall sensor connection and the far right DB9 is for the LCD programmer. Complete main wiring harness and injector harness are supplied, made to your custom specs if desired along with Hall sensor and LCD programmer cord. Standard main harnesses and injector drive harnesses are 6 feet long from ECU to most sensors, Hall sensor cables are 7 feet standard. Programmer cable from ECU to programmer is 6 feet. Please note that there will be a $42US additional charge for custom length wiring harnesses and that custom harnesses will usually delay orders an additional day or so.

Injector harness is supplied with connectors, made to your specifications

Please note that we can only supply D or L-Jetronic injector plugs. Some late model Japaneses engines use oval shaped connectors which we can't supply. These must be grafted onto our harness.

Waterproof Weatherpack connectors as shown below are pre-installed on harnesses.

Options Explained

The options listed on the price list page are additions that you can make to your system or order to enhance its capability or ease of tuning. These are extra cost options, not included in the basic system price.On any options requiring a relay, we recommend the use of ours as these have a resistor across the contacts to prevent noise spikes back into the ECU which may cause ECU resets or error codes. The price of the option includes the relay, wiring and costs to develop the original software for them. We do this to keep costs as low as possible for those not needing the options. If you use all the engineered pieces, you will have the least likelihood of problems.

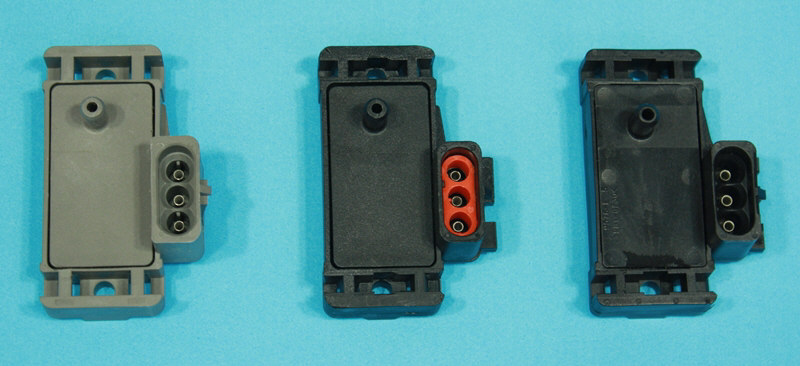

MAP Sensors

From left to right: 1 Bar, 2 Bar, 3 Bar MAP sensors

MAP sensors are required on most systems to measure engine load. All turbocharged and supercharged engines must use a MAP sensor. Installation is simple, with only a vacuum line connection to the intake manifold and plugging in the harness connector. MAP sensors are supplied in 3 different calibrations: 1 Bar for naturally aspirated engines, 2 Bar for engines running up to 15 psi (1 Bar) of boost and 3 Bar for engines running up to 30 psi (2 Bar) of boost. 1 Bar $80US, 2 Bar $90US, 3 Bar $105US.

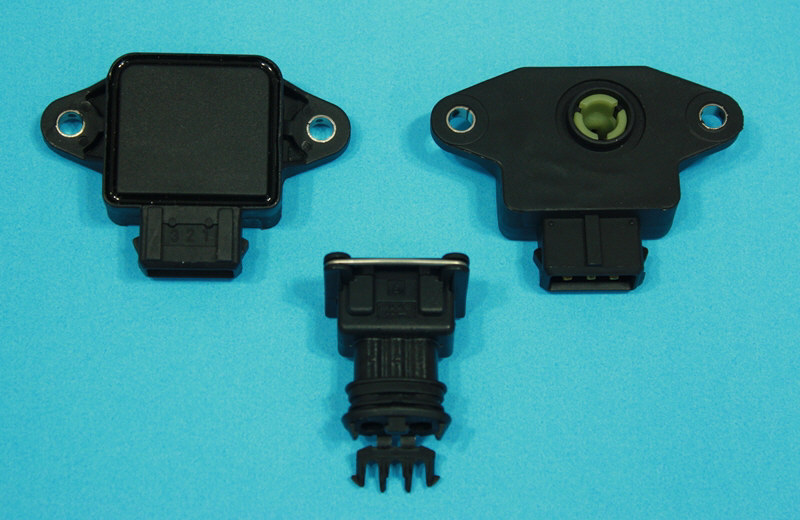

Throttle Position Sensors

All systems require a TPS for acceleration enrichment. Systems configured for TP load sensing also use this sensor for throttle angle information. Any OEM potentiometer type TPS can be used with SDS. If you don't already have one of these, we can supply one as shown above. These have a 5/16 (8mm) female, D drive. More info and photos are available on the Hardware Page at: tps.htm. $94US

Knock Control

The knock option consists of extra circuitry added inside the ECU, an extra wire and connector on the wiring harness and the knock sensor itself. Knock control allows the ECU to retard the ignition timing on E and F systems automatically if knocking is detected. This is a good backup to the standard boost retard capabilities of the E and F units for many engines but we don't recommend using the sensor as the primary means of reducing detonation. We also don't recommend this option on most air cooled engines or engines which are mechanically noisy as it can be difficult or impossible to tune out this noise while still allowing the ECU to "hear" actual knocking. Our knock control system is compatible with many OE knock sensors used on GM, Mitsubishi, Nissan, Toyota and Subaru engines. Bosch 0 261 321 046 and 0 261 231 001 are also compatible. If you can use the factory sensor, the price of this option is reduced from $100US, which normally includes a Bosch sensor, to $30US. Check with us for compatibility. Complete details on programming and installation of this option are available in the E and F installation manuals online.

Fuel Pump Relay

The fuel pump relay option consists of circuitry added to the ECU, a control wire and a modified relay to switch the fuel pump on and off via the ECU. When the ECU is powered up, the ECU turns on the fuel pump relay for 2.8 seconds to pressurize the fuel system. If the ECU does not detect crank rotation within this time, it will shut off the pump until it does. Advantages of this over simply hooking your pump up to the ignition switch are; you don't have the pump running without the engine running which is handy for programming and in the event of an accident, if the engine stops, the fuel pump also stops after 2.8 seconds to reduce the chances of fire. Some racing sanctioning bodies also require this feature on EFI equipped vehicles. On engines originally equipped with Bosch L- Jetronic systems with door type airflow meters, there is a microswitch in the airflow meter used to control the fuel pump. If the meter or wiring harness is removed, you will have to rewire the pump to another power source. This option makes your life easier. $30US

Fast Idle

The fast idle option consists of extra circuitry added to the ECU, a control wire, a modified relay and an air bypass solenoid. When the coolant or CHT is below a certain temperature, which is now user programmable, the ECU commands the solenoid to open and bypass aditional air past the throttle plate to increase idle speed. As the engine warms up near normal operating temperature, the ECU closes the solenoid to restore the normal hot idle rpm setting. This option is recommended in cooler climates where warmup time is extended and oil viscosity reduces the cold idle rpm to unacceptably low levels. Scraping the frost and snow off of your car is certainly easier with this option. On most engines, the solenoid allows the engine to achieve between 800 and 1500 rpm during the warmup cycle. Installation requires running 5/16 vacuum hose from the air filter to the solenoid and from the solenoid to the intake manifold. The control system is either on or off. There is no proportional control of rpm. $105US

RPM Relay

This option consists of extra circuitry added to the ECU, a control wire and a modified relay. This option is popularly used to control variable valve timing systems such as Honda VTEC and Toyota VVT. It can also be used to control variable induction passages such as the Toyota TVIS. A third use is control of a shift light or any other rpm related function. The on/off point is user programmable in 250 rpm increments from 1500 to 9750 rpm. It is a single stage system, so if you program the on point at 6000 rpm, the relay is activated closed above 6000 and open (off) below 6000 rpm. $30US

Electric Fan Relay

This option consists of a control wire, software and a relay. It is used to control an electric fan via the water temperature sensor. On/off points are programmable but the actual water temperatures are not shown. These points are adjustable between 0 and 255. On/off points are usually set between 20 and 30 with standard GM sensors. Some experimentation is required while watching Gauge 1 mode. $30US

Supercharger Relay

This option consists of extra circuitry added to the ECU, a control wire, software and a relay. It is used primarily to control the supercharger clutch on Toyota 4AGZ engines. On/off points are set by manifold pressure points, user programmable. Relay is normally open at low manifold pressures, leaving the clutch disengaged. As manifold pressure rises to the set point, the ECU closes the relay contacts to energize the clutch. $30US

A/C Solenoid

The option consists of an air bypass solenoid of the same type supplied for the fast idle option. This solenoid is hooked up directly to the air conditioning clutch circuit. When the a/c clutches in, the solenoid opens to increase engine idle speed by bypassing air past the throttle plate. This prevents sagging rpm with a/c operation. 5/16 vacuum hose connections to the air filter and intake manifold are required. This option is not controlled by the ECU. As of 03/23/01, we have a method to use the fast idle solenoid to also work as the a/c solenoid so you don't need the additional valve if you order the fast idle option.

Older Systems. Which One do I Have?

The series of computer is printed on the top of the ECU- EM-1, 2, 3 or 4. EM-1 ECUs have 2 connectors on the side, EM-2s have 3, EM-3, EM-4, EM-5 and EM-6s have 4. D systems control fuel only. These usually have no crank sensor but have a green tach wire in the main harness. E systems control fuel and spark with a distributor. These have a single element crank sensor, a blue coil trigger wire and no green tach wire. F systems control fuel and spark and use a coil pack to replace the distributor. These have a twin element crank sensor and no green tach wire on the main harness. The programmer will display series number and type in the bootup mode when first powered up along with software version installed. Please be sure of which system you have before you correspond with us or order replacement parts.