Superior Design= Superior Performance

Last Update: July 22/25

***Please note that SDS Aero products are only for use on Experimental/ amateur built aircraft. Not for use on certified aircraft.***

SDS CPI-2 Aviation Ignition System

The CPI-2 is the evolution of the original CPI aircraft electronic ignition system. CPI-2 builds to a large degree on customer feedback. People wanted a smaller panel footprint, over voltage protection, integrated LOP function, larger display, aviation standard keypad color, LCD dimming, aural warning output, automatic backup battery switchover with integrated battery solution and the ability to data log. These features along with others, makes CPI-2 the most capable Experimental aviation ignition system on the market.

CPI-2 kit for Lycoming 4 cylinder engine. No wiring harnesses shown but these are included. Note that as of Feb. 3/25, systems for US customers will not include some items shown here due to recent tariffs. We'll include a list of vendors and part numbers to obtain these parts within the USA. Contact us for the latest pricing.

CPI-2 kit for Lycoming 6 cylinder engine.

Advanced Features

Racetech/SDS has been selling EIs to the aviation market since 1997. We've built our reputation and business on reliable, affordable products and the best customer and tech support in the industry. You'll find us friendly, helpful and timely in our responses before and after the sale.

Note the CPI-2 should only be used with resistor type spark plugs and good quality, EMI/ RFI suppression type plug wires. Never use non-resistor plugs or solid core wires. We can supply quality MSD plug wire, boots and terminals to fit most engines.

Easy Programming and The Lean of Peak Switch Advantage

SDS introduced LOP timing advance to the Experimental EI market in 2015. While other aviation EIs give you a canned timing curve which is often secret and hard to adjust, usually requiring extra cost options to observe and change, SDS CPI makes basic timing adjustments quick and easy to do and our LOP switch optimizes ignition advance when running LOP. This feature extracts all possible energy from the fuel, picking up a few knots which are lost when running leaner mixtures.

Simple ignition curve programming in logical 100 rpm and 1 degree increments

Programmable LOP advance amount

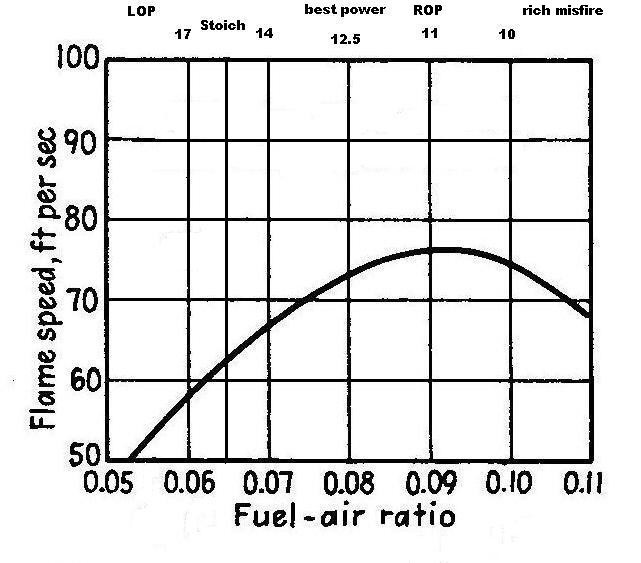

The figure below illustrates how combustion flame speed changes with air/ fuel ratio.

Notice how much flame speed slows down with lean mixture here. The SDS LOP switch advances timing when you are running LOP to achieve peak cylinder pressure at the optimal point for best torque.

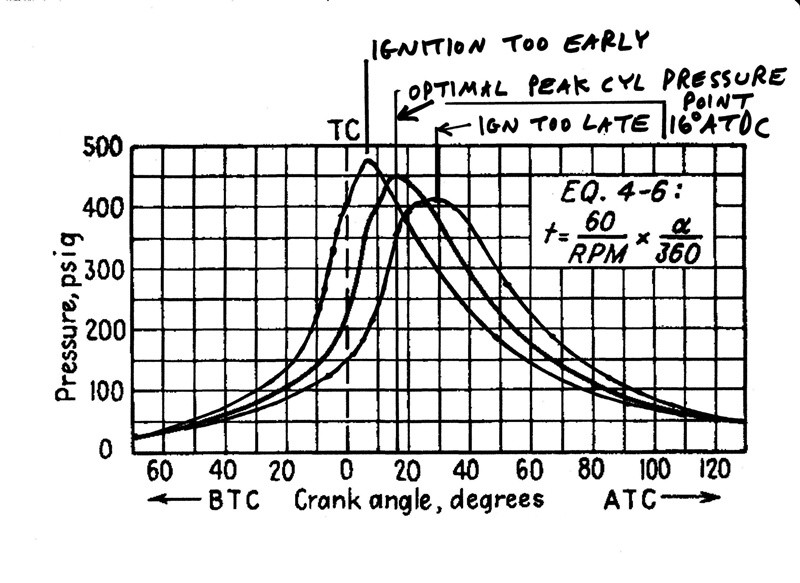

Notice how advanced or retarded timing affects the pressure vs. crankpin position curve. Unlike magnetos with fixed timing, CPI can deliver optimal ignition timing under all mixture, rpm and load conditions. EIs which cannot adjust timing when running LOP, lose efficiency compared with CPI

Available in both single and dual controller configurations

Optional backup battery detail. Tray kit is $140US not including battery. Order Powersonic battery PS-1227 from Amazon or Ebay.

Optional mounting tray detail

Battery and tray footprint is 5.25 long, 2.75 wide and 4.75" high

Please note, this battery will run a dual system for about 20 minutes at 2500 rpm in the event that the main alternator and main battery go down. If you need more power duration for your typical missions, we suggest you install a larger battery than this one and/or a second backup alternator.

More Screens

Panel mount programmer showing Gauge Mode. Size is 2.8 X 2.8 X 1.2 deep. Serial cables exit the back.

Displays main and backup battery voltage and shows which source is providing power.

Audio control window

Adjustable screen brightness

CPI-2 can log to a Windows device

Thermal imaging test of the PCB during development and testing phase

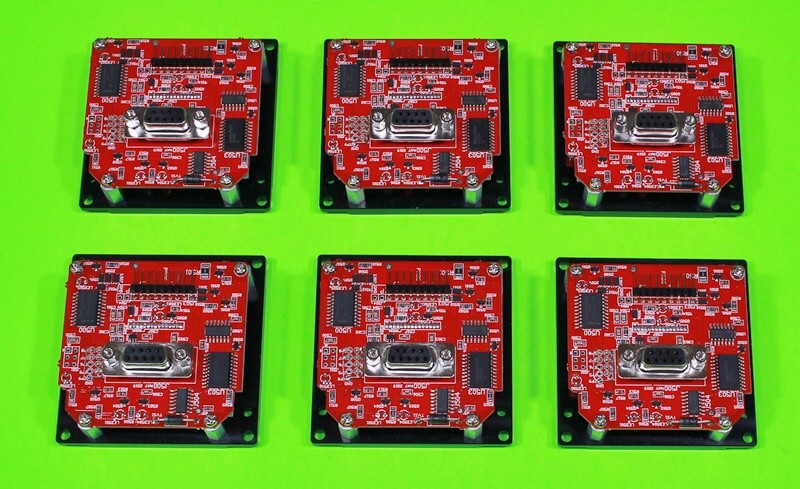

CPI-2 programmers under construction

Optional vacuum block kit gives smoothest possible vacuum signal to the controller by averaging and damping pressure pulses. 1/8NPT fittings screw into your primer or injector ports. Block mounts with Adel clamps to 3/4" engine mount tubes. 4 cyl. block kit (left) $50US. 6 cyl. block kit (right) $75US

Videos

CPI-2 Temperature testing CPI-2 programmer: https://youtu.be/1hzjaygmFJc

CPI-2 Hardware and basic features: https://www.youtube.com/watch?v=xq8jIAEU27o&t=32s

CPI-2 running on our test Continental O-200 engine: https://www.youtube.com/watch?v=ykeNFBLUYEg&feature=youtu.be

Please note: our magnet mounting system for Lycoming engines is not compatible with the Sky Dynamics lightweight flywheels, new Lycoming flywheels lacking the 12 tooling holes around the periphery or factory dual pulley groove flywheels. We do have a solution for Airflow Systems aftermarket flywheels for driving a/c compressors.

Documentation

CPI2 programmer panel drawing updated Mar. 15/18

CPI2 installation manual updated July 22/25

CPI2 hardware installation manual updated Mar. 20/22

CPI2 pinout list updated Nov. 7/19

Lycoming 4 cylinder magnet mounting Revised Oct. 23/19

Lycoming 6 cylinder magnet mounting Revised may. 24/24

Switch/ breaker layout for CPI-2

Coil and controller current draw chart (One coil pack and one controller. Double for dual systems)

Note that as of Feb. 3/25, systems for US customers will not include some items shown in the photos due to recent tariffs. We'll include a list of vendors and part numbers to obtain these parts within the USA. Contact us for the latest pricing.

Add $60 for 4 cylinder engines and $90 for 6 cylinder engines using long reach plugs

Our backup battery tray and wiring will be a $140 option on all systems. Battery is not included. Order a Powersonic PS-1227 from Ebay or Amazon.

Optional vacuum block kit prices: $50US for 4 cylinder engines, $75 for 6 cylinder engines.

A single controller can also fire both sets of plugs if desired. Add $411 to the single controller price for 4 cylinder engines and $574 for 6 cylinder systems.

Information We Need When Placing an Order

To place your order, it's best to email or phone us to discuss your project as each system is custom made and tailored for each client. We'll get a list of all your details, discuss wiring lengths etc. and then quote you. You then pay by Visa or Mastercard, wire transfer, E-transfer for Candian customers.

Phone 403-671-4015

E-mail: racetech7@proton.me

MSD Plug Wires and Boots

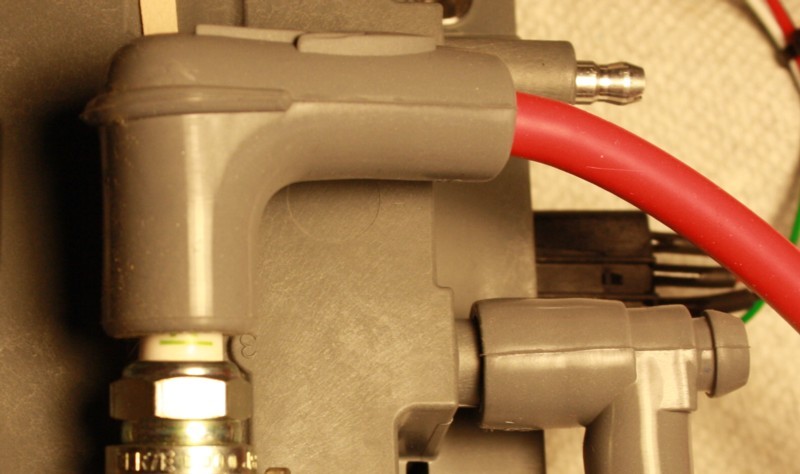

Be sure you push the plug and coil boots all the way down to engage the terminals fully. There should be about an 1/8 inch gap as shown in the photo below

Video for building your MSD plug wire set

MSD Plug Wire Part Numbers

The following bulk PNs fit all coil packs:

34049 8.5mm red Superconductor wire

34615 90 degree terminal (plug and coil)

34555 90 degree coil boot

34515 90 degree plug boot

Recommended MSD plug wire crimping tool PN 35051

Please ohm check your completed wires. They should measure around 50 ohms per foot of length.

Magneto Parts to Remove on 6 Cylinder Lycoming Engines

Exploded view of magneto parts on Lycoming 540 engines: 540magparts.pdf

When replacing the mags on 6 cylinder Lycoming engines, be sure to remove the gear/ cup (6), cush drive (2) and pilot bearing (7) as shown above. Be very careful not to drop any of the parts into the sump! The extension housing (4) may be removed or left in place as desired

Service Bulletins

Sept. 2/19 (revised April 17/20) Setting Magnet Position

We've eliminated the need to set Magnet Position with a timing light on Lycoming engines. For engine using the dual pickup, set Primary ECU Magnet Position to 97 and Backup to 88. For single pickup installations, set it to 92.

June 25/19 Service Bulletin Regarding Possible Hall Sensor Mounting Bolt Interference With Front Case Through-Bolts

Be sure the Hall sensor bolts don't hit the case bolts inside the threaded stainless steel standoffs. If they do, place another washer under the head of the Hall sensor bolts. Additional standard and light washers are provided with the assembly for this purpose and to establish proper sensor to flywheel clearance.

April 26/19 Service Bulletin Regarding 18 to 14mm Spark Plug Adapter Installation

Due to a number of broken brass plug adapters, we've changed the procedure for installing these as follows: 1. Thread the spark plug into the adapter 2. Torque the assembly into the cylinder head using the PLUG hex to 19 ft./lbs. 3. Torque the ADAPTER further to 25 ft./lbs. Use only a thin stripe of anti-seize compound on the plug and adapter. Do not coat the threads. Although we've done multiple yield tests on the adapters torqued into a fixture and they fail at 32-35 ft./lbs., a number of people were snapping them at the originally recommended torque of 22 ft./lbs.

For other aviation product information, click here: Aircraft

Customer Installations

Mike Gordon's F-4 Rocket which flew from SC to Germany April 2024

Over Greenland

Around 175 KTAS on 7.3 gph running LOP

Tom McNerney's Lancair Legacy at Reno 2023. CPI-2 equipped.

Jeff Ackland's Glasair CPI-2 equipped

Ray Ward's super clean F4 Raider at Osh '21. CPI-2 equipped

RV-14A in Australia

Danny Melnik's beautiful Rocket in Florida

Dual Hall sensor mount detail on Conti O-240 (Dave Magaw)

Installation on Rick Conklin's O-320 Dualmag powered RV-9A

Clean panel install of the CPI-2 programmer

Firewall mounted coil pack

Installation on Kevin Taylor's RV-8

Great idea for easy access

Kevin is truing 188 knots here running LOP

Installation on Mike Kellems' RV-3B

Some photos of Mike Juckes' installation on his Rocket

Charlie Rogers Hall sensor cable protection idea uses Delrin block